Are you struggling with stuffy air and harmful fumes in your workshop? A proper workshop ventilation system can change everything.

It not only keeps the air fresh but also protects your health and boosts your work efficiency. Imagine breathing easy, feeling energized, and focusing fully on your projects without worrying about dust, smoke, or odors. You’ll discover how the right ventilation setup can transform your workspace into a safer and more comfortable place.

Keep reading to find out what to look for and how to make your workshop a healthier environment for you and everyone who steps inside.

Credit: www.printables.com

Importance Of Workshop Ventilation

Proper workshop ventilation is essential for safety and comfort. It helps remove harmful fumes and dust from the air. Clean air improves worker health and boosts productivity. Ventilation also controls temperature and moisture, preventing damage to tools and materials. A well-ventilated workshop lowers risks and meets legal standards.

Health Risks Of Poor Air Quality

Bad air in workshops causes many health problems. Dust and fumes can irritate eyes and lungs. Long exposure may lead to serious diseases like asthma or bronchitis. Workers may feel tired, dizzy, or have headaches. Proper ventilation removes these pollutants, keeping air fresh and safe.

Fire And Explosion Hazards

Workshops often contain flammable dust and gases. Without good airflow, these substances can build up. A single spark can cause fire or explosion. Ventilation systems help disperse dangerous fumes. This reduces the chance of accidents and protects workers and property.

Regulatory Requirements

Many countries have strict rules on workshop ventilation. These laws ensure workplaces meet safety and health standards. Employers must install and maintain ventilation systems. Regular inspections check if air quality is safe. Following regulations avoids fines and legal problems.

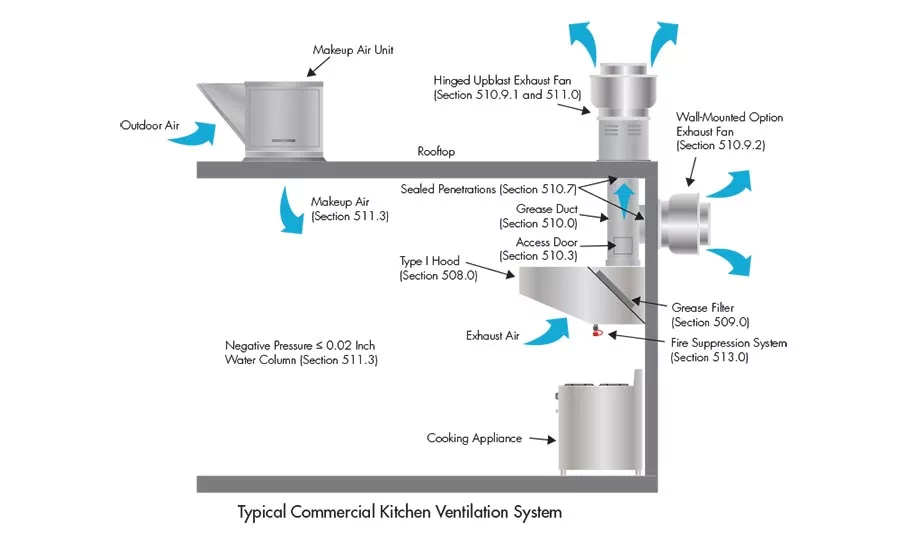

Credit: renewaire.com

Types Of Ventilation Systems

Choosing the right ventilation system for your workshop can greatly impact air quality, safety, and overall comfort. Different types of ventilation systems serve unique purposes depending on the size of your space, the nature of your work, and the pollutants you need to manage. Understanding these options helps you make informed decisions that protect your health and boost productivity.

Natural Ventilation

Natural ventilation uses openings like windows, doors, and vents to let fresh air in and push stale air out. It relies on wind and temperature differences rather than mechanical devices. This method is cost-effective and energy-saving, but it depends heavily on weather conditions and may not be enough for workshops with heavy dust or fumes.

Have you noticed how opening a window on a breezy day instantly freshens the air? That simple action is natural ventilation at work. However, in colder seasons or enclosed workshops, this might not be practical or effective enough to maintain safe air quality.

Mechanical Ventilation

Mechanical ventilation uses fans or blowers to control airflow actively. It allows you to regulate the amount and direction of air movement regardless of outside weather. This system is ideal for larger workshops or those handling materials that produce dust, vapors, or odors.

One practical tip is to install adjustable fans so you can increase airflow during intense tasks and reduce it when less ventilation is needed. This flexibility saves energy and keeps your environment comfortable. Have you considered how controlling airflow can improve both your safety and energy bills?

Local Exhaust Ventilation

Local exhaust ventilation (LEV) targets pollution right at its source before it spreads through the workshop. It uses hoods, ducts, and filters to capture contaminants like dust, fumes, or smoke immediately. LEV is crucial when you work with hazardous materials or perform processes like welding, sanding, or chemical handling.

Imagine welding without a fume extractor nearby—those fumes linger and affect everyone’s health. Installing LEV systems can drastically reduce your exposure to harmful substances. Have you checked if your workshop’s air quality could benefit from such focused ventilation?

Key Components Of Ventilation Systems

Having an efficient workshop ventilation system isn’t just a luxury—it’s a necessity. It keeps the air fresh, removes harmful particles, and ensures a healthy environment for everyone in the space. But what makes a ventilation system truly effective? Let’s break down the key components that make it all work seamlessly.

Fans And Blowers

Fans and blowers are the heart of any ventilation system. They ensure that stale air is pushed out and fresh air is brought in. Whether you’re dealing with small exhaust fans or industrial-grade blowers, their role is to maintain consistent airflow throughout the workshop.

Choose the right size and type of fan based on your workshop’s needs. For instance, a woodworking shop with lots of dust might need high-powered blowers, while a painting booth may require explosion-proof fans. Always look for energy-efficient models to save on electricity costs without compromising on performance.

Ductwork Design

Ductwork plays a crucial role in directing air where it needs to go. Poorly designed ducts can create bottlenecks, reducing the system’s efficiency. You want a layout that minimizes bends and obstructions to allow smooth airflow.

Use durable materials like galvanized steel or aluminum for your ducts, especially in workshops with high humidity or corrosive chemicals. And don’t forget to seal the joints properly—leaky ducts can waste energy and compromise air quality.

Air Filters And Purifiers

Air filters and purifiers ensure that the air circulating in your workshop is clean and safe to breathe. They trap dust, fumes, and other harmful particles before they can spread. This is especially important in spaces where fine particles or toxic chemicals are present.

Consider installing HEPA filters for maximum efficiency. For workshops that deal with odors or volatile organic compounds (VOCs), adding carbon filters or air purifiers with UV light technology can make a huge difference. Regularly check and replace filters to keep the system working efficiently.

Does your workshop’s ventilation system include all these components? If not, it might be time to upgrade. Your health and productivity depend on it!

Credit: www.pmmag.com

Designing Effective Ventilation

Creating a workshop ventilation system that works effectively is not just a technical task—it’s about creating a space where you can breathe easy and work comfortably. Whether you’re cutting wood, welding metal, or working with chemicals, proper ventilation protects your health and boosts productivity. But how do you ensure your system is designed for maximum efficiency? Let’s break it down into key steps.

Calculating Airflow Needs

Start by understanding how much air your workshop requires. This depends on the size of your space and the type of work you do. For instance, a small woodworking shop may need less airflow than a large metal fabrication workshop.

The formula for calculating airflow is simple: multiply the workshop’s volume (length × width × height) by the number of air changes per hour (ACH) recommended for your activities. For general workshops, 6–8 ACH is typical, but tasks like welding might require up to 12 ACH. Don’t just guess—get specific with your numbers for a safer environment.

Do you work with strong fumes or fine dust? If yes, consider a higher airflow rate to maintain clean air. Always err on the side of better ventilation rather than cutting corners.

Placement Of Vents And Exhausts

Where you place your vents and exhausts matters as much as how many you install. Poor placement can leave dead zones with stagnant air. Position exhaust vents near sources of pollution, such as workbenches or machines that emit fumes or dust.

For fresh air intake, vents should be placed on the opposite side of the room from your exhaust to create a good airflow path. This cross-ventilation ensures contaminants are pushed out effectively.

Also, think vertically. Heat and fumes rise, so install exhaust vents higher up to remove hot, polluted air. Fresh air intakes, on the other hand, can be positioned lower to bring in cooler, cleaner air.

Balancing Fresh Air Intake

Exhausting dirty air is only half the job—you also need to replace it with fresh air. Without a proper balance, your workspace could develop negative pressure, making doors hard to open or pulling in unfiltered air from unwanted places.

To maintain balance, ensure your intake vents allow enough fresh air to match the air being exhausted. A good rule is to have intake openings equal in size to your exhaust openings.

Don’t forget filters on your intake vents, especially if your workshop is in a dusty or polluted area. Clean filters regularly to maintain efficiency and prevent airflow blockages.

Have you noticed how much fresher your workspace feels when the ventilation is just right? That’s the power of good design in action. By calculating airflow, placing vents strategically, and balancing fresh air intake, you can create a workshop environment that supports health, comfort, and productivity.

Maintenance And Monitoring

Maintaining and monitoring a workshop ventilation system keeps the air clean and workers safe. Regular care prevents breakdowns and ensures steady airflow. Monitoring helps spot issues early and keeps the system efficient.

Regular System Inspections

Check all parts of the ventilation system often. Look for damage, loose connections, or blockages. Inspect fans, ducts, and vents for dust build-up. Clean or repair any worn or broken components quickly. Inspections help avoid costly repairs and protect air quality.

Filter Replacement Schedules

Filters trap dust and harmful particles. Replace them on a set schedule to keep air fresh. Dirty filters reduce airflow and strain fans. Follow manufacturer guidelines for replacement timing. Use quality filters to improve system performance and worker health.

Air Quality Sensors

Install sensors to measure dust, fumes, and gas levels. Sensors provide real-time data about air conditions. They alert you if harmful levels rise. Use this information to adjust ventilation settings. Sensors help maintain a safe and healthy workspace.

Benefits Of Upgrading Ventilation

Upgrading a workshop ventilation system brings many key benefits. Cleaner air improves health and comfort. Workers feel better and breathe easier. Productivity often rises as the workspace becomes more pleasant. Proper ventilation also helps meet safety rules and lowers legal risks. These advantages make upgrading a smart choice for any workshop.

Improved Worker Health And Comfort

Good ventilation removes dust, fumes, and harmful gases. It keeps the air fresh and reduces allergies. Workers experience fewer headaches, dizziness, and respiratory problems. Comfortable air temperature and airflow help maintain focus and energy. Healthy workers take fewer sick days and feel more satisfied.

Enhanced Productivity

Clean air supports better concentration and work quality. Proper airflow reduces overheating or cold spots in the workshop. Workers move and operate tools more efficiently in a comfortable space. Less fatigue means tasks finish faster and with fewer errors. A well-ventilated workshop creates a positive work environment.

Compliance And Liability Reduction

Upgraded ventilation meets industry safety standards and codes. It reduces risks of accidents caused by poor air quality. Proper systems lower the chance of fines or shutdowns by inspectors. Employers protect themselves from legal claims related to health issues. Clear documentation of ventilation upgrades supports compliance efforts.

Frequently Asked Questions

What Is A Workshop Ventilation System?

A workshop ventilation system removes contaminants, dust, and fumes from the air. It ensures proper airflow and maintains a safe working environment.

Why Is Ventilation Important In Workshops?

Ventilation prevents buildup of harmful fumes, improves air quality, and ensures worker safety. It also reduces risks of respiratory issues and equipment overheating.

How Does A Ventilation System Improve Air Quality?

Ventilation systems filter out pollutants, dust, and toxic particles. They exchange stale air with fresh air, enhancing indoor air quality.

What Types Of Ventilation Systems Are Used In Workshops?

Common systems include natural ventilation, mechanical exhaust fans, and HVAC systems. Selection depends on workshop size and specific needs.

Conclusion

A good workshop ventilation system keeps air fresh and safe. It removes dust, fumes, and harmful gases fast. Clean air helps workers stay healthy and focused. Proper ventilation also stops equipment from overheating. Choose a system that fits your workshop size and needs.

Regular maintenance keeps the system working well. Safe air means better work and fewer health problems. Don’t ignore ventilation—it protects your team and your tools. A well-ventilated workshop runs smoother every day.