Have you ever wondered what makes your furniture, vehicles, or gadgets stay securely in place? If you’ve ever taken a closer look, you might have noticed small but mighty components called bolts.

These essential fasteners are everywhere, playing a crucial role in holding together the things you use daily. But what exactly is a bolt, and why should you care? Understanding bolts can save you from future headaches, whether you’re fixing a wobbly chair or tackling a DIY project.

By the end of this article, you’ll know more about bolts than you ever thought possible. You’ll discover how they work, what makes them unique, and why they’re vital to the integrity of countless structures. Dive in and satisfy your curiosity; knowing the ins and outs of bolts might just become your newest fascination!

Credit: www.hlc-metalparts.com

Bolt Basics

Bolt Basics are essential for many construction and repair tasks. Bolts secure materials together. They offer strength and stability. Understanding their types and uses is crucial.

Definition And Characteristics

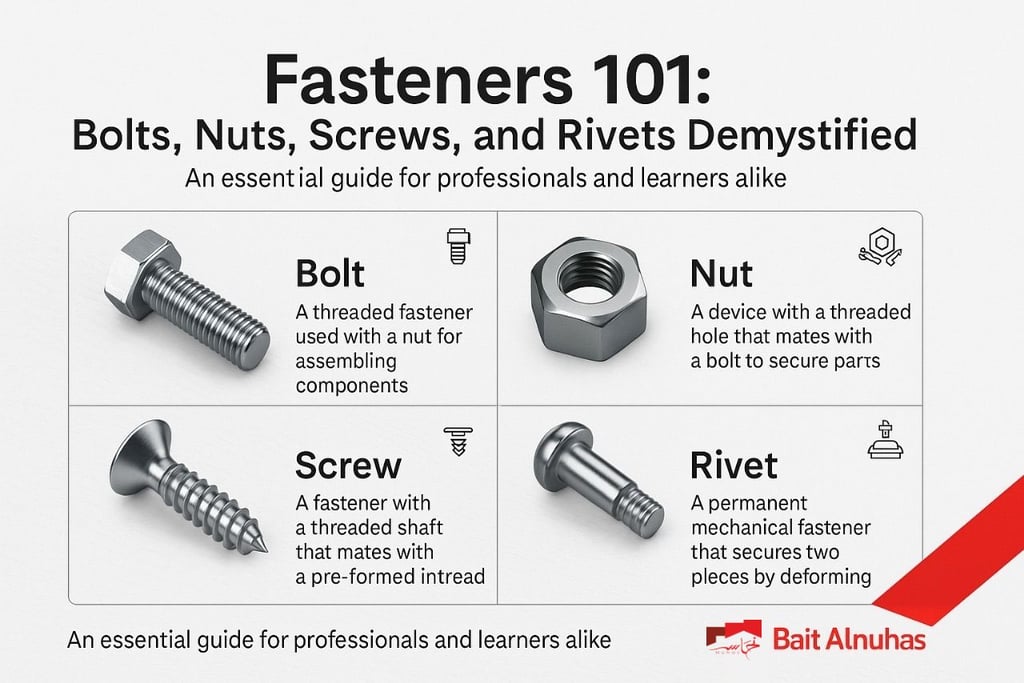

A bolt is a type of fastener. It typically has a cylindrical shape. The head is on one end. A threaded shaft is on the other. Bolts require nuts to fasten. They are not self-tapping. They need pre-drilled holes. Bolts provide strong connections. They resist shear and tensile forces.

Common Materials Used

Bolt materials vary based on usage. Steel is the most common. It offers durability and strength. Stainless steel resists rust and corrosion. Perfect for outdoor use. Brass is softer. Used in decorative applications. Aluminum is lightweight. Ideal for areas needing less weight.

Credit: www.mudgefasteners.com

Bolt Types

Bolts are strong fasteners used to hold objects together securely. They feature a threaded shaft and a matching nut. Various types include hex bolts, carriage bolts, and anchor bolts.

When it comes to fasteners, bolts are among the most versatile and commonly used. They come in various types, each designed for specific applications. Understanding different bolt types can help you choose the right one for your project. Let’s dive into some of the most popular bolt types and what makes them unique.Hex Bolts

Hex bolts are probably the most recognizable type of bolt. Their six-sided head offers an easy grip for tools, making them ideal for fastening in tight spaces. These bolts are perfect for construction projects where strength and durability are crucial. Next time you’re assembling furniture or building a deck, consider hex bolts for their reliability.Carriage Bolts

Carriage bolts are unique due to their rounded head and square neck. This design prevents the bolt from spinning when you tighten the nut. They are often used in wood connections because the square neck fits snugly into a pre-drilled hole, ensuring stability. If you’re working on a wooden fence or a timber frame, carriage bolts might be your best friend.Lag Bolts

Lag bolts, or lag screws, are heavy-duty fasteners typically used in wood applications. They’re known for their ability to hold up under heavy loads, making them perfect for projects like securing beams or assembling log cabins. Ever struggled with a stubborn piece of wood that won’t stay put? Lag bolts can provide the grip you need.Eye Bolts

Eye bolts are designed with a loop at one end, making them ideal for attaching ropes or cables. They are frequently used in rigging or lifting applications. Think of them as the go-to option when you need to hang something securely. Whether you’re suspending a hammock or hoisting equipment, eye bolts offer a dependable solution. Each type of bolt serves a specific purpose. Which one aligns with your current project needs? Understanding these types can make a noticeable difference in your project’s outcome.Bolt Applications

A bolt is a type of fastener with a threaded shaft designed for securing materials together. Commonly paired with a nut, bolts provide strong and reliable connections in construction and machinery. Their versatility makes them essential for various applications, from simple household repairs to complex industrial projects.

Bolts are one of the most ubiquitous fasteners, used extensively in various applications that demand strength and reliability. Whether you’re working on a small household project or constructing a skyscraper, bolts play a critical role in holding components together securely. Let’s explore how bolts are applied in different scenarios, and how they contribute to the integrity of your projects.Construction And Structural Uses

In construction, bolts are the backbone of structural integrity. They are used to assemble steel frameworks, connecting beams and columns to form the skeleton of buildings. The durability and load-bearing capacity of bolts make them ideal for bridges, buildings, and other large-scale structures. Imagine standing on a bridge, feeling secure in knowing that thousands of bolts are working together to support your weight and the weight of vehicles passing by. This reliability is why bolts are favored in construction—ensuring safety and stability in every project.Mechanical And Automotive Applications

In the realm of mechanics and automotive engineering, bolts are essential for assembling engines, chassis, and other components. They hold parts in place, withstand vibrations, and endure the high temperatures and pressures found in engines. Ever changed a tire? You’ve encountered lug bolts, which secure the wheel to the vehicle. Their strength is crucial for keeping you safe on the road, highlighting the importance of choosing the right bolt for automotive applications.Household And Diy Projects

Bolts are not confined to heavy-duty uses; they also shine in household and DIY projects. Whether you’re assembling furniture or hanging shelves, bolts provide the strength needed to hold everything together. Picture yourself assembling a bookshelf. Bolts make the task straightforward, ensuring the shelves won’t collapse under the weight of your books. They empower you to tackle DIY tasks with confidence, transforming your home one project at a time. How do you decide which bolt to use for your next project? Consider the material, size, and the load it needs to bear. With the right bolt, you can ensure durability and safety, no matter the task.Choosing The Right Bolt

Choosing the right bolt is crucial for any construction or repair project. Bolts come in many sizes, materials, and grades. Selecting the correct one ensures durability and safety. Let’s explore the factors and grades to consider.

Factors To Consider

- Material:Steel is common, but stainless steel resists rust.

- Size:Length and diameter must fit the application.

- Thread Type:Coarse threads are stronger, fine threads allow precision.

- Finish:Galvanized bolts resist corrosion, plain ones are cheaper.

- Environment:Consider exposure to weather and chemicals.

Understanding Bolt Grades

Bolt grades indicate strength and durability. Higher grades mean stronger bolts. Grades are marked on bolt heads.

| Grade | Strength | Common Use |

|---|---|---|

| Grade 2 | Low | General household projects |

| Grade 5 | Medium | Automotive applications |

| Grade 8 | High | Industrial machinery |

Choose the right grade to match the strength needed for your project.

Bolt Installation

Installing a bolt may seem straightforward, but understanding the nuances can make a difference in the stability and longevity of your project. Whether you’re fastening a bookshelf or assembling machinery, the right technique ensures safety and efficiency. Let’s dive into the essentials of bolt installation.

Tools Required

- Wrench or Socket Set:Essential for tightening bolts to the correct tension.

- Torque Wrench:Useful for precision to avoid over-tightening.

- Screwdriver:Sometimes needed for bolt assemblies with attached screws.

- Thread Locker:A chemical compound that prevents loosening from vibration.

Having the right tools on hand can save you both time and frustration. Imagine you’re halfway through a project and realize you don’t have the correct wrench size. It can be a real momentum killer.

Step-by-step Process

- Prepare the Surface:Ensure the surfaces to be joined are clean and aligned. Dirt or misalignment can weaken the joint.

- Insert the Bolt:Place the bolt through the holes of the objects you’re fastening. Double-check the bolt’s length to ensure it’s appropriate for the thickness of the materials.

- Add a Washer:If required, place a washer on the threaded end before adding the nut. Washers distribute the load and protect surfaces.

- Hand-Tighten the Nut:Begin by hand to ensure the threads are engaged correctly. Cross-threading can damage both the bolt and the nut.

- Use a Wrench to Tighten:Secure the nut with a wrench or socket. Make sure to hold the bolt head steady using another tool to prevent it from turning.

- Apply Torque:If precision is needed, use a torque wrench to tighten to the specified torque value. This prevents damage from over-tightening.

- Check Your Work:Give the assembly a gentle shake. If it feels loose, recheck each step.

Have you ever completed a project only to find it falls apart shortly after? Proper bolt installation can prevent such mishaps. The attention to detail, like using a torque wrench, sets apart a shaky structure from a solid one.

Remember, the devil is in the details. Are you sure you’re tightening enough, but not too much? Ensuring each component is correctly applied makes all the difference.

Bolt Maintenance

A bolt is a type of fastener used to hold materials together. It typically requires a nut for secure attachment. Regular maintenance ensures its durability and performance in various applications.

Bolt maintenance is crucial for ensuring the longevity and performance of your fasteners. Regular upkeep not only helps in preventing potential failures but also saves time and money in the long run. Whether it’s your car, home project, or machinery, giving attention to bolt maintenance can make a significant difference in safety and efficiency.Regular Inspection Tips

Inspecting your bolts regularly is the first step in maintenance. Schedule routine checks to identify any signs of damage or loosening. Keep a checklist handy: – Look for rust or corrosion on the bolt surface. – Check if the bolt is loose or misaligned. – Ensure the bolt head and threads are intact and not stripped. Don’t underestimate the power of touch. Sometimes, running your fingers over the bolt can help detect irregularities that aren’t immediately visible.Signs Of Wear And Replacement

Worn-out bolts can compromise the integrity of your project. Knowing when to replace them is vital. Watch out for these signs: – Visible rust or corrosion that doesn’t clean off. – Warped or bent bolt body. – Threads that are flattened or damaged. Ever struggled with a bolt that just wouldn’t tighten? That’s a clear sign it might need replacement. Consider keeping spare bolts on hand. This simple step can save you from unexpected delays in your projects. Is there a bolt maintenance story you’ve experienced that taught you an invaluable lesson? Remember, sharing insights can help others avoid similar pitfalls.

Credit: www.facebook.com

Frequently Asked Questions

What Defines A Bolt As A Fastener?

A bolt is defined by its threaded shaft designed for insertion into pre-drilled holes. It requires a nut for fastening, creating a secure hold. Bolts are typically used to assemble parts, providing strength and stability. Their design allows for easy removal and reassembly, making them versatile fasteners.

How Do Bolts Differ From Screws?

Bolts differ from screws mainly in their application and design. Bolts require a nut to fasten, whereas screws thread directly into materials. Bolts are used for larger assemblies, providing more strength and stability. Screws are more versatile for smaller or individual components, often used in woodworking or metalworking.

What Materials Are Bolts Made From?

Bolts are commonly made from steel, stainless steel, and brass. Steel bolts are strong and durable, suitable for heavy-duty applications. Stainless steel bolts resist corrosion, ideal for outdoor or moisture-prone environments. Brass bolts offer a decorative finish and moderate strength, used in applications requiring aesthetic appeal.

Where Are Bolts Commonly Used?

Bolts are commonly used in construction, automotive, and machinery applications. They provide strong, reliable connections in structural assemblies. In automotive industries, bolts hold engine components together. Machinery relies on bolts for secure, stable parts. Their versatility makes them essential in many industries for strength and durability.

Conclusion

A bolt is more than a simple fastener. It holds things together firmly. Bolts come in various sizes and materials. They serve many purposes in construction and machinery. Choosing the right bolt is crucial for safety. Without the right bolt, structures might fail.

Always check the bolt type before use. Remember, bolts are strong but need proper installation. This ensures safety and stability. Next time, choose wisely for your project. Bolts play a vital role in our daily lives. Keep learning about them for better use.

Stay informed, stay safe.