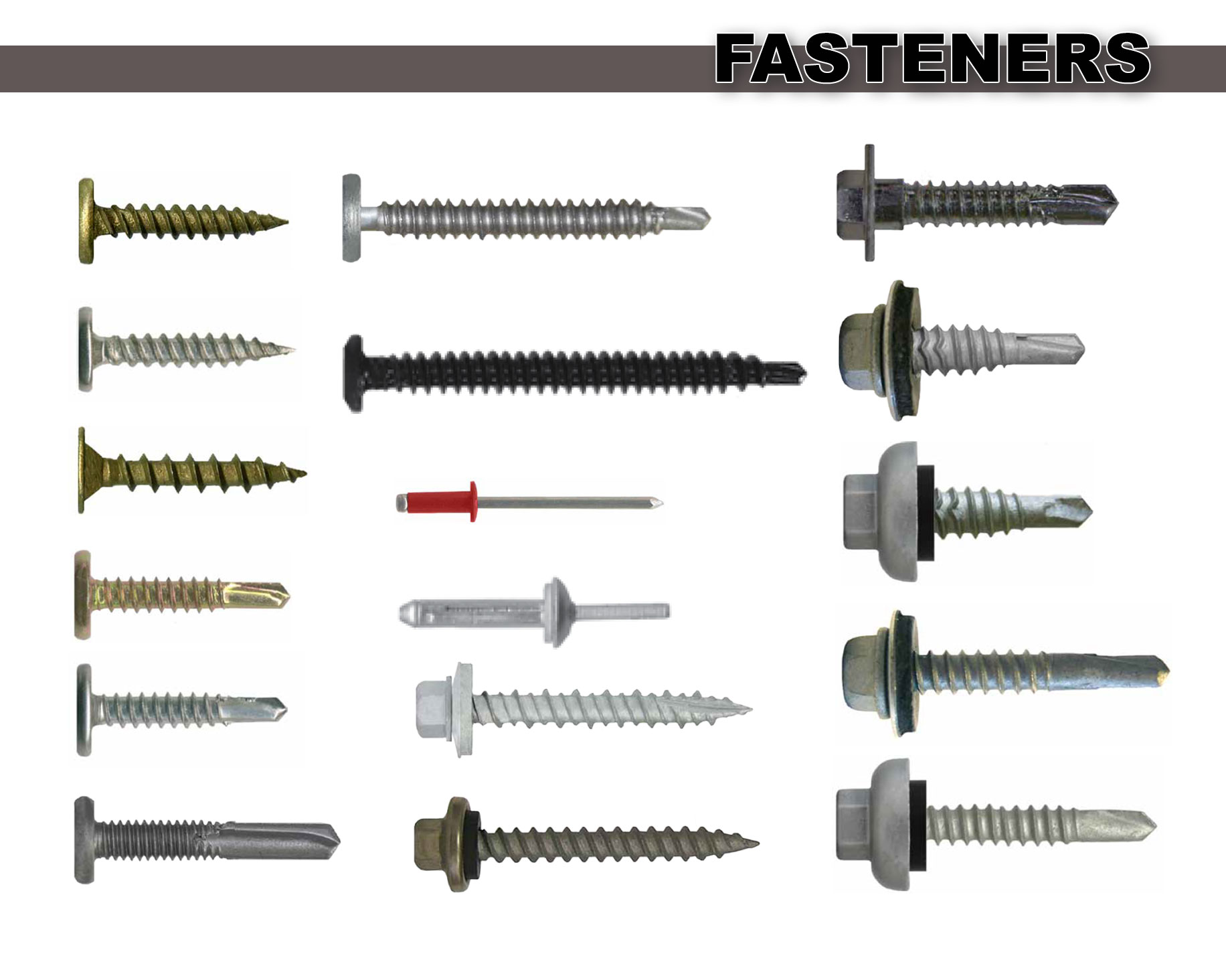

Are you tired of fumbling with the wrong fasteners for your projects? Whether you’re an avid DIY enthusiast, a professional builder, or someone who simply wants to hang a picture frame, knowing the right fasteners can save you time, effort, and frustration.

Imagine the satisfaction of choosing the perfect fastener that effortlessly holds everything in place. You’ll discover the five basic types of fasteners that are essential for any toolkit. By the end, you’ll not only have a clear understanding of each type but also the confidence to tackle any project that comes your way.

So, why settle for trial and error when you can become a fastener expert in just a few minutes? Let’s dive in and transform your fastening skills.

Credit: en.wikipedia.org

Screws

Screws are among the five basic types of fasteners, essential for holding materials together. They provide strong, secure connections in construction and DIY projects.

Screws are essential fasteners used in many projects. They hold things together by creating a secure grip. Their threaded design makes them easy to install and remove. Screws are versatile, making them popular in construction and everyday tasks. Understanding different types helps in choosing the right one for any job.Common Types Of Screws

There are several common screw types. Each serves a specific purpose:- Wood Screws:Ideal for fastening wood pieces. They have a sharp point.

- Machine Screws:Used in metal work. Often paired with nuts.

- Sheet Metal Screws:Designed for metal sheets. They have a pointed tip.

- Concrete Screws:Used in masonry. They are tough and durable.

- Drywall Screws:Perfect for hanging drywall. They have a bugle-shaped head.

Applications Of Screws

Screws are used in various applications. They are common in:- Construction:Building frames and structures.

- Furniture Assembly:Joining parts securely.

- Automotive:Securing parts in vehicles.

- Electrical:Fastening components safely.

- DIY Projects:General home repairs and crafts.

Nails

Nails are essential fasteners in construction and carpentry. They offer strong, reliable connections between materials. Used for framing, they are versatile and come in various sizes.

Nails are one of the most common fasteners used in various projects. They are simple yet versatile, playing a crucial role in construction and carpentry. Nails are typically made of metal and driven into materials using a hammer or nail gun. They hold objects together by creating friction and tension. Understanding the different types of nails helps in selecting the right one for your project.Varieties Of Nails

Nails come in various shapes and sizes to suit different purposes. Here are some common types:- Common Nails:These nails are thick and strong. Ideal for structural work.

- Finishing Nails:They have small heads and are used for detailed work. Perfect for trim and molding.

- Box Nails:Thinner than common nails. Suitable for lighter projects.

- Roofing Nails:Designed with a large head. Used mainly for installing shingles.

- Brad Nails:Small and thin. Used for light woodworking and delicate crafts.

Uses Of Nails

Nails serve various purposes in construction and crafts. They are essential in:- Framing:Common nails are often used to join wooden frames.

- Finishing Work:Finishing nails hold trim and moldings without visible marks.

- Roofing:Roofing nails secure shingles to rooftops.

- Cabinetry:Brad nails provide a clean look in furniture and cabinetry.

- General Carpentry:Box nails are ideal for lighter carpentry tasks.

Bolts

Bolts are among the five basic types of fasteners. They are used to hold materials together securely. Bolts often work with nuts to create a strong connection.

Bolts are fundamental components in the world of fasteners, playing a vital role in holding together everything from furniture to massive industrial machines. These threaded fasteners come in various designs and sizes, tailored to meet specific needs and applications. Their versatility and strength make them indispensable in both household projects and professional construction work. But what types of bolts are there, and how do you choose the right one for your task? Let’s dive into the different kinds of bolts and their usage scenarios.Different Kinds Of Bolts

Bolts come in a variety of shapes and sizes, each suited for specific applications. Hex bolts are probably the most recognizable, featuring a hexagonal head and used in construction and repair jobs. Then there are carriage bolts, known for their rounded head and square neck, perfect for wood applications where a smooth finish is desired. Lag bolts are your go-to when you need to fasten heavy objects like timber, thanks to their sharp, pointed end that can penetrate wood easily. Anchor bolts are essential in masonry work, securing objects to concrete surfaces. And don’t forget about eye bolts, which have a looped head, making them ideal for attaching ropes or cables.Bolt Usage Scenarios

Choosing the right bolt for your project can mean the difference between a secure fit and a potential disaster. Imagine you’re assembling a wooden deck; lag bolts are perfect here, providing the strength needed to hold large pieces of timber together securely. For securing a heavy machine to a concrete floor, anchor bolts are your best friend, ensuring stability and safety. If you’re hanging a swing from a beam, eye bolts offer a convenient point to attach chains or ropes. Meanwhile, hex bolts prove invaluable in automotive repairs and machinery assembly, offering a strong and reliable connection. For a smooth finish on visible surfaces, carriage bolts are the ideal choice, keeping everything neatly in place without protruding heads. Next time you’re faced with a fastening challenge, ask yourself: What kind of bolt does my project truly need? Understanding the different bolt types and their usage can save you time and effort, ensuring your projects are not only strong but also long-lasting.Washers

Washers are essential components in the world of fasteners. They are flat, disk-shaped pieces that distribute the load of a screw or bolt. Their primary function is to prevent damage to surfaces and ensure a secure fit. Without washers, fasteners might not hold as effectively, leading to loose connections. Proper usage of washers can enhance the durability and stability of structures.

Types Of Washers

Washers come in various types, each designed for specific purposes. Here are some common types:

- Flat Washers:These are the most basic type. They distribute load evenly.

- Lock Washers:They prevent fasteners from loosening over time.

- Fender Washers:Larger in diameter, they spread load over a larger area.

- Spring Washers:Designed to provide tension and absorb shock.

- Sealing Washers:They prevent leaks by creating a seal.

Purpose Of Washers

Washers serve multiple purposes in fastening systems. They protect surfaces from damage caused by fasteners. Washers also help distribute pressure evenly, which prevents wear and tear. In vibrating environments, they reduce movement and maintain tightness. Some washers offer a sealing function, preventing fluid leaks. Their ability to prevent corrosion enhances longevity. Washers ensure that fasteners perform effectively and reliably.

Rivets

Rivets, a staple in fastening, permanently join materials. They’re one of the five basic fastener types, alongside screws, bolts, nuts, and washers. Rivets are widely used in construction and manufacturing for their strength and durability.

Rivets are essential fasteners in many industries. These small metal pins hold materials together permanently. Unlike screws, rivets don’t require threads. Instead, they expand when installed, creating a secure bond. Rivets are ideal for joining sheets of metal, leather, or plastic. They are widely used in construction, automotive, and aerospace sectors.Various Rivet Styles

Rivets come in many styles. Solid rivets are the most common. They are durable and strong. Blind rivets are used where only one side is accessible. They are ideal for hollow structures. Tubular rivets are lightweight and easy to install. They are perfect for light-duty tasks. Split rivets have legs that expand for a tight grip. They work well in soft materials. Lastly, drive rivets are hammered into place, providing a quick solution.Rivet Application Areas

Rivets are versatile. In construction, they join steel beams. They provide sturdy connections for bridges. In the automotive industry, rivets secure body panels. They are vital for car assembly. Aircraft use rivets for fuselage and wing attachment. This ensures structural integrity. Leather goods, like bags and belts, use rivets for decoration. They add strength and style. Lastly, electronics use rivets in circuit boards. They offer reliable connections.

Credit: dmimetals.com

Credit: www.facebook.com

Frequently Asked Questions

What Are Common Types Of Fasteners?

Fasteners are essential components in construction and manufacturing. Common types include bolts, screws, nuts, washers, and rivets. Each serves unique purposes, such as securing materials or providing structural stability. Understanding their functions helps in choosing the right fastener for your project.

How Do Bolts Differ From Screws?

Bolts and screws differ mainly in their application. Bolts require nuts to secure materials, while screws are self-tapping. Bolts are used for heavy-duty applications, whereas screws are suitable for light to medium tasks. Recognizing these differences ensures optimal fastening solutions.

Why Are Washers Used With Fasteners?

Washers provide stability and distribute load evenly across surfaces. They prevent fasteners from loosening and protect materials from damage. Washers are vital in applications where vibration is common. They enhance the longevity and effectiveness of the fastening system.

What Is The Purpose Of Nuts In Fasteners?

Nuts are threaded components that secure bolts, enhancing fastening strength. They ensure the bolt remains tight in applications subject to vibration. Nuts come in various types, including hex and lock nuts, each offering specific benefits. Selecting the right nut ensures a secure, lasting connection.

Conclusion

Fasteners play a vital role in construction and repair. Bolts, screws, nails, rivets, and washers form the foundation of most projects. Each type serves a unique purpose. Bolts and screws secure parts together. Nails offer quick solutions. Rivets provide strong, permanent connections.

Washers prevent wear and tear. Understanding these fasteners helps make better decisions. Choose wisely for each specific need. Proper selection ensures durability and safety. Next time you tackle a project, remember the basic types. They simplify tasks and improve results.

Fasteners might be small, but their impact is significant.