Are you tired of dust taking over your workspace and making clean-up a constant battle? A reliable shop dust collection system can change everything.

It not only keeps your shop clean but also protects your health and improves your tools’ performance. Imagine working in a space where dust is controlled and your focus stays sharp. Ready to discover how the right dust collection system can transform your workshop?

Keep reading to find out what to look for and how to choose the best one for your needs.

Benefits Of Dust Collection

Investing in a shop dust collection system offers more than just cleanliness. It directly impacts your health, safety, and the overall efficiency of your workspace. Understanding these benefits can help you make smarter decisions about maintaining your shop environment.

Health And Safety

Dust particles in your workshop can cause serious respiratory problems over time. By using a dust collection system, you reduce the amount of airborne dust, protecting your lungs and those of anyone working around you.

Think about how much time you spend cutting or sanding materials. Without proper dust control, harmful particles can linger, increasing the risk of accidents and long-term health issues.

Improved Air Quality

Clear air makes your workspace more comfortable and productive. Dust collection systems trap fine dust that normal sweeping or vacuuming misses, keeping the air fresh and breathable.

Have you noticed how stale or dusty your shop feels after a busy day? A good dust collector changes that by continuously removing particles from the air, making it easier to focus on your tasks.

Enhanced Equipment Lifespan

Dust buildup can clog machinery and cause overheating or wear. Removing dust regularly helps your tools and machines run smoothly and last longer.

Imagine your expensive saw or sander working like new for years because dust no longer interferes with its parts. That’s a real saving on repair and replacement costs.

Cleaner Workspace

A tidy shop is easier to work in and reduces the chance of mistakes or accidents. Dust collection systems help maintain a clean floor and surfaces, so you spend less time cleaning and more time creating.

Would you rather spend your day cleaning up dust or working on your projects? A dust collector makes the choice easy, keeping your workspace organized and ready for action.

Credit: powertecproducts.com

Types Of Dust Collection Systems

Dust collection systems are essential for keeping workshops clean and safe. They capture dust and debris created during woodworking or metalworking. Different types of dust collectors suit various needs and budgets. Choosing the right system depends on the size of your shop and the type of dust produced.

Single-stage Systems

Single-stage systems pull dust and chips directly into a collection bag or bin. They work well for small shops with light dust loads. These systems are simple and cost-effective but may clog easily with fine dust.

Two-stage Systems

Two-stage systems separate large chips from fine dust before filtering. The first stage collects heavy debris in a bin. The second stage uses a filter to trap smaller dust particles. This method keeps filters cleaner and lasts longer.

Cyclone Collectors

Cyclone collectors use centrifugal force to separate dust from the air. Dust spins around in a cyclone chamber and falls into a collection bin. Clean air exits through the top. These systems handle large dust volumes efficiently.

Baghouse Filters

Baghouse filters use fabric bags to trap fine dust particles. Air passes through the bags, leaving dust behind. These systems are common in larger shops and industrial settings. They require regular maintenance to keep filters clean.

Portable Units

Portable dust collectors are compact and easy to move around the shop. They connect to different machines as needed. Ideal for small workshops or occasional use. These units offer flexibility but may have lower capacity.

Key Components

When setting up a shop dust collection system, understanding its key components is crucial. Each part plays a vital role in maintaining clean air and ensuring your tools and workspace remain dust-free. Let’s break down the essential components that make a dust collection system efficient and functional.

Dust Collector Unit

The dust collector unit is the heart of your system. It’s the main device that captures and stores dust and debris from your shop. Whether you choose a single-stage or two-stage collector, ensure it has enough capacity to handle the volume of dust your tools generate.

For small shops, a compact wall-mounted unit might suffice. Larger spaces might require an industrial-grade collector with a bigger dust bin. Always match the dust collector’s capacity with your shop’s needs to prevent clogging and inefficiency.

Ductwork And Hoses

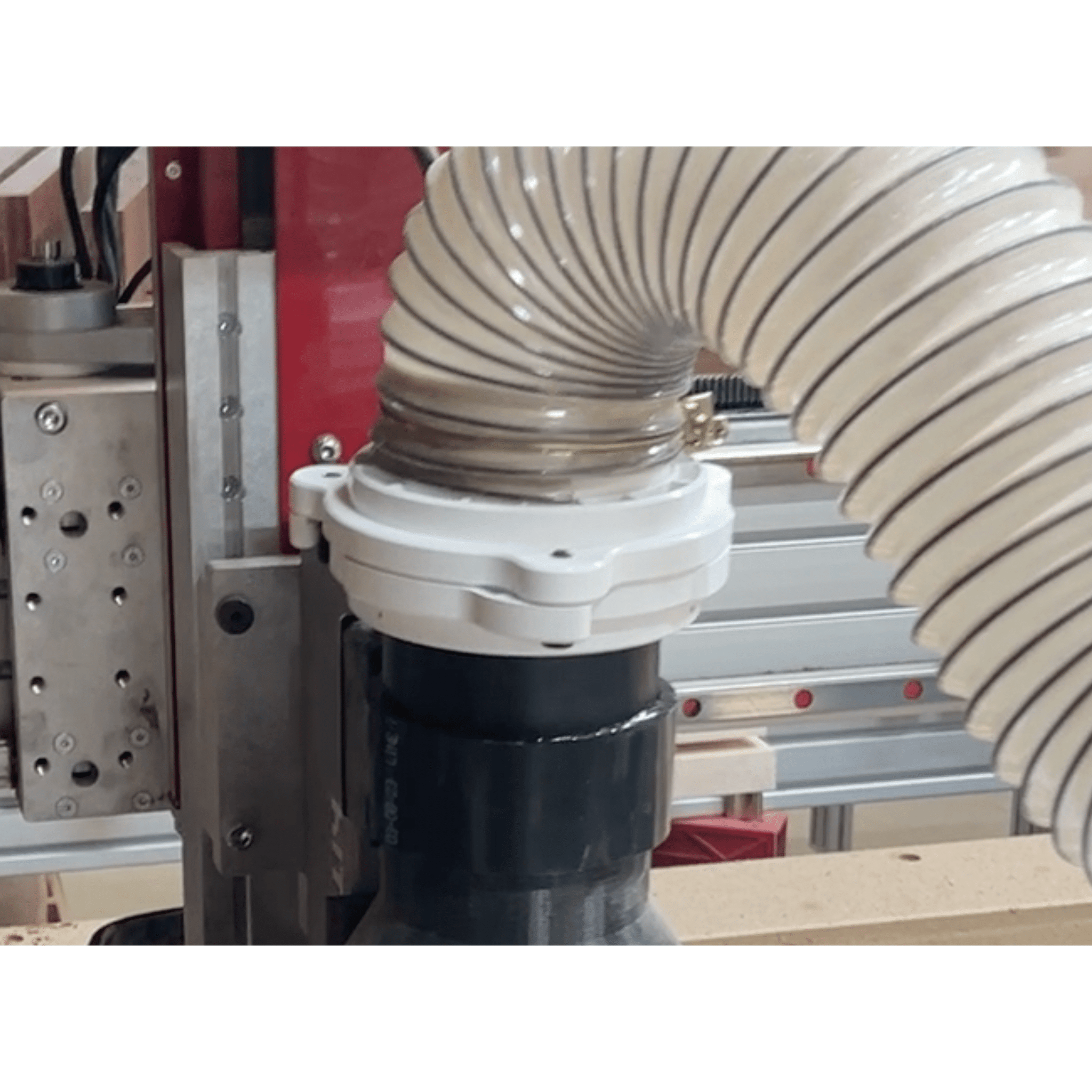

Ductwork and hoses are like the veins of your dust collection system. They carry dust from your tools to the collector. Choose durable materials like metal ducting or heavy-duty flexible hoses to ensure longevity.

Keep your duct runs as short and straight as possible. Long, winding ducts reduce airflow efficiency. Consider using smooth interior surfaces to minimize resistance and maximize dust capture.

Blast Gates

Blast gates help you control airflow by opening and closing individual ducts. These small but essential components improve suction efficiency by directing airflow to the tool in use. Without blast gates, you risk losing suction power across your entire system.

Install blast gates near each tool for easy access. Opt for metal gates for durability, especially if your system handles heavy debris. Don’t overlook their importance—they can make or break your system’s performance.

Filtration Media

Filtration media determines how effectively your system removes fine dust particles from the air. Most dust collectors use filter bags or cartridge filters. Cartridge filters are more efficient as they trap smaller particles and are easier to clean.

If you’re working with materials like MDF or hardwood, prioritize a filter with a lower micron rating. This ensures better air quality and less exposure to harmful dust. Regularly check and clean or replace filters to maintain peak performance.

Motors And Fans

The motor and fan are the driving forces behind your dust collection system. They create the suction needed to capture dust and debris. A more powerful motor translates to better airflow and higher efficiency.

Check the motor’s horsepower (HP) and the fan’s cubic feet per minute (CFM) rating. Match these to your shop size and the type of tools you use. A mismatch can result in poor suction or overworked equipment.

Does your current dust collection system have all these components? If not, consider upgrading for better performance. A well-designed system not only keeps your workspace clean but also protects your health and extends the life of your tools.

Sizing Your System

Sizing your shop dust collection system correctly ensures efficient dust removal and safer air quality. A well-sized system prevents clogs, reduces energy use, and keeps your workspace clean. Understanding key factors helps you choose a system that fits your needs perfectly.

Calculating Airflow Needs

Airflow is the volume of air your system moves. It is measured in cubic feet per minute (CFM). Each tool in your shop needs a certain airflow to capture dust effectively. Add the airflow needs of all tools you use at once. This total helps you find the right system size.

Determining Cfm Requirements

CFM depends on tool type and dust load. Larger tools like planers or sanders need more CFM. Smaller tools such as routers require less. Check tool manuals or online guides for exact CFM values. Ensure your dust collector meets or exceeds this total CFM.

Assessing Shop Layout

Shop layout affects duct length and bends. Longer ducts with many turns reduce airflow. Keep ducts as straight and short as possible. Plan tool locations close to the dust collector. A good layout lowers airflow loss and improves system efficiency.

Selecting Proper Duct Sizes

Duct size impacts airflow speed and dust capture. Too small ducts cause clogs and pressure drops. Too large ducts reduce dust velocity, allowing dust to settle. Match duct diameter to tool CFM needs. Common sizes range from 4 to 6 inches for most shops.

Installation Tips

Installing a shop dust collection system correctly can save you time, improve air quality, and keep your workspace cleaner. Paying attention to the details during installation makes a big difference in how well your system performs. Here are some practical tips to help you set up your system efficiently and effectively.

Planning Duct Routes

Plan your duct routes before you start installing. Shorter, straighter runs reduce airflow resistance and boost suction power.

Avoid sharp bends and unnecessary fittings, which can trap dust and reduce efficiency. Think about where your tools are placed and design routes that serve them best.

Have you noticed how dust tends to settle in long horizontal ducts? Sloping ducts slightly can help dust move toward the collector instead of clogging the pipes.

Sealing And Insulation

Seal all duct joints tightly using metal tape or mastic to prevent air leaks. Even small leaks can cause a big drop in performance.

Insulate ducts if your workshop faces extreme temperatures. This prevents condensation, which can cause rust and blockages over time.

Imagine losing suction because of a tiny gap you missed sealing—take the time to double-check every connection.

Positioning Collectors

Place your dust collector close to the main work area to minimize duct length and maximize suction. But leave enough space for maintenance and airflow around the unit.

Keep the collector elevated or on a stable platform to avoid dust buildup near the floor. This also protects the unit from dampness.

Think about noise levels too—position the collector where it won’t disrupt your workflow or cause distractions.

Electrical Considerations

Ensure your dust collector has a dedicated electrical circuit with the correct amperage. This prevents overloads and potential hazards.

Use a properly rated switch or remote control for easy operation. It’s safer and more convenient when you can start or stop the system without walking over to it.

Ground the system correctly to avoid electrical shocks. Have a qualified electrician check your setup if you’re unsure.

Maintenance Practices

Proper maintenance keeps your shop dust collection system running smoothly. Regular upkeep ensures efficient performance and extends its lifespan. Neglecting maintenance can lead to poor air quality and higher energy costs. Follow these practices to keep your system in top shape.

Regular Filter Cleaning

Filters trap dust and debris, preventing them from entering the workspace. Clean them regularly to maintain airflow and efficiency. A clogged filter reduces suction power and increases strain on the motor. Depending on usage, clean filters weekly or monthly. Use compressed air or a soft brush to remove buildup.

Inspecting Ductwork

Ducts transport dust from tools to the collection system. Inspect them for leaks, blockages, or loose connections. Leaks reduce suction power and allow dust to escape into the air. Check seals and joints for tightness. Replace damaged sections or apply sealant to fix minor leaks.

Checking Motor Performance

The motor drives the dust collection system. Monitor its performance for unusual noises or overheating. A struggling motor may indicate clogged filters or worn components. Lubricate moving parts and check electrical connections. Regular inspections prevent costly repairs and downtime.

Emptying Collection Bins

Full collection bins reduce the system’s capacity to store dust. Empty them before they overflow to maintain performance. Overflowing bins can clog filters and ductwork. Dispose of collected dust responsibly to avoid environmental hazards. Make bin emptying a routine part of your maintenance schedule.

Common Challenges

Running a shop dust collection system can be a game-changer for maintaining a clean and safe workspace. However, like any system, it comes with its fair share of challenges. Understanding these common issues can help you optimize performance and avoid unnecessary headaches.

Clogged Ducts

Clogged ducts are a frequent problem that can reduce the effectiveness of your dust collection system. Dust and debris often accumulate over time, narrowing the ductwork and restricting airflow. This not only affects suction but also increases the risk of damaging the system.

To combat this, inspect your ductwork regularly. Use a flexible cleaning tool or compressed air to clear out blockages. If clogs happen frequently, consider upgrading to larger ducts or installing a pre-separator to catch larger debris before it enters the system.

Noise Issues

Excessive noise can make working in your shop unbearable. Many dust collection systems generate a loud hum or whine, especially when running at high capacity. This can quickly become a distraction or even a safety concern if it drowns out important sounds like tools in operation.

To reduce noise, look for insulated ducting or install a muffler on the system’s exhaust. Placing the dust collector in a separate, enclosed area can also help keep the noise levels in check. Don’t forget ear protection for yourself and your team—it’s a simple yet effective solution.

System Overloading

Overloading the system happens when it’s tasked with more than it can handle. This can occur if you’re using tools that generate excessive dust or connecting too many machines at once. Overloading not only reduces performance but can also shorten the lifespan of the motor.

To prevent this, know your system’s capacity. Use blast gates to control airflow and only operate one or two tools at a time. If you frequently exceed your system’s limits, it might be time to invest in a more powerful unit.

Inefficient Dust Capture

Nothing is more frustrating than a dust collection system that fails to capture dust effectively. This is often due to improper placement of ducts, poor suction, or leaks in the system. As a result, dust can remain airborne, posing health risks and making cleanup harder.

Check for leaks in the ductwork and seal them with aluminum tape or clamps. Position the dust ports as close to the source of dust generation as possible. If your system still struggles, upgrading to a higher-quality filter or cyclone separator can make a significant difference.

Have you faced any of these challenges in your workshop? Addressing them head-on can make your dust collection system much more efficient and reliable. A little effort goes a long way toward keeping your workspace clean and enjoyable to use.

Upgrading Your System

Upgrading your shop dust collection system can drastically improve air quality and efficiency. Small changes often lead to big results, especially when dust control directly impacts your health and productivity. Consider these practical upgrades to make your system work smarter and cleaner.

Adding Additional Collectors

Adding more dust collectors can help manage dust at multiple points in your shop. Instead of relying on one central unit, spread collectors closer to machines that produce the most dust.

This reduces the distance dust travels through ducts, preventing clogs and improving suction. Have you noticed certain machines create more airborne dust? Adding dedicated collectors for those areas might be the solution.

Improving Filtration

Upgrading filters is one of the easiest ways to enhance your dust collection system. Higher-quality filters capture finer particles and improve air cleanliness.

Consider filters with HEPA ratings if you work with very fine dust or allergens. Upgrading filters regularly also keeps your system running at peak performance, preventing dust buildup and costly repairs.

Automating Controls

Automating your dust collection system can save energy and ensure it runs only when needed. Sensors can detect machine operation and activate the dust collector automatically.

This prevents the system from running unnecessarily, reducing wear and energy costs. Have you ever forgotten to turn off your dust collector? Automation can handle that for you, improving convenience and efficiency.

Energy Efficiency Enhancements

Improving energy efficiency can reduce your shop’s operating costs significantly. Upgrades like variable speed drives let you adjust fan speed based on dust load.

Sealing leaks in ductwork also prevents loss of suction and wasted energy. Small changes, such as switching to energy-efficient motors, add up over time. What energy-saving tweaks could you make in your system today?

Cost Considerations

Choosing the right shop dust collection system involves careful cost considerations. It is important to understand the financial impact beyond just buying the equipment. Costs include the initial price, ongoing expenses, and possible savings over time. This knowledge helps in selecting a system that fits your budget and needs.

Initial Investment

The initial investment covers the purchase price of the dust collection system. Prices vary based on size, brand, and features. Larger systems with advanced filters cost more. Installation fees may add to the total expense. Planning for this upfront cost is essential for budgeting.

Operating Expenses

Operating expenses include energy use and maintenance costs. Dust collectors consume electricity to run motors and fans. Filters and bags need regular replacement. Labor costs for cleaning and upkeep also add up. Considering these expenses helps avoid surprises later.

Long-term Savings

Efficient dust collection can save money over time. It improves air quality and protects equipment. Reduced health risks lower employee sick days. Less machine wear means fewer repairs and longer lifespan. These benefits often offset the initial and operating costs.

Budget-friendly Options

Budget-friendly systems exist for small shops or limited funds. Compact units use less energy and cost less upfront. Simple designs require less maintenance. Modular systems allow future upgrades as budgets allow. Choosing wisely ensures effective dust control without overspending.

Credit: www.walmart.com

Safety Tips

Safety in your shop’s dust collection system should never be an afterthought. Ignoring key precautions can lead to serious hazards, including fires, equipment damage, and health risks. Paying attention to safety tips not only protects you but also keeps your workspace efficient and reliable.

Avoiding Combustible Dust

Combustible dust is a hidden danger in many shops. Fine dust particles can ignite easily, causing explosions or fires. You need to clean your dust collection system regularly to prevent buildup, especially in corners and ducts.

Never underestimate the power of good housekeeping. Use vacuum systems designed for dust, not just sweeping or blowing dust around. Ask yourself: Are you removing dust as soon as it forms, or letting it accumulate?

Proper Grounding

Static electricity can build up in dust collection systems, creating sparks that ignite dust. Proper grounding and bonding of your equipment are essential to avoid this risk. Check that all metal parts are connected to a reliable grounding system.

Simple checks, like testing continuity with a multimeter, can save you from disaster. If you’ve ever felt a spark when touching metal machinery, that’s a warning sign. Don’t ignore it—make grounding a priority.

Personal Protective Equipment

Your safety gear is your first line of defense. Always wear a dust mask or respirator to protect your lungs from harmful dust particles. Safety goggles and hearing protection are equally important when operating noisy, dusty equipment.

Think about how often you skip these protections because of discomfort or haste. Changing habits here can prevent long-term health issues. Is your PPE comfortable enough to wear consistently? If not, try different options until you find the right fit.

Emergency Procedures

Knowing what to do if something goes wrong can save lives. Have clear emergency procedures posted and make sure everyone in your shop knows them well. Practice fire drills and ensure fire extinguishers are accessible and inspected regularly.

Consider the worst-case scenarios: How quickly can you shut down the dust collection system? Do you know where the emergency exits are? Preparing for emergencies turns fear into control.

Credit: magswitch.com

Frequently Asked Questions

What Is A Shop Dust Collection System?

A shop dust collection system removes dust and debris from workshops. It improves air quality, protects equipment, and ensures a cleaner workspace.

Why Is Dust Collection Important In Woodworking?

Dust collection prevents health hazards like respiratory issues. It reduces fire risks and keeps tools functioning efficiently by minimizing dust buildup.

How Do I Choose The Right Dust Collection System?

Consider your shop size, tools, and dust volume. Check system capacity, filtration quality, and compatibility with your tools.

Can A Dust Collection System Reduce Airborne Particles?

Yes, it captures fine dust particles, improving air quality. This protects your health and creates a safer working environment.

Conclusion

A good shop dust collection system keeps your workspace clean. It helps protect your health by reducing dust in the air. Choosing the right system saves time and effort during cleanup. It also extends the life of your tools by preventing dust buildup.

Remember, a clean shop means better work and safety. Invest in a system that fits your needs and space. Clean air, clean tools, and a safer shop—simple and smart.