When you work with a grinding machine, your safety should always come first. One small mistake can lead to serious injuries or damage.

That’s why knowing the right safety precautions and having a clear checklist is essential before you start. You’ll discover simple but powerful steps to protect yourself and keep your workspace safe. Follow these tips closely, and you’ll feel more confident and prepared every time you use a grinding machine.

Don’t risk it—make safety your priority now. Keep reading to learn exactly what you need to do.

Credit: www.gz-supplies.com

Types Of Grinding Machines

Grinding machines come in various types, each designed for specific tasks and materials. Knowing which machine suits your project can improve both safety and efficiency. Understanding these types helps you choose the right tool and follow the correct safety measures.

Surface Grinders

Surface grinders create a smooth finish on flat surfaces. They use a spinning abrasive wheel to remove material, making them ideal for precision work. If you’ve ever needed to sharpen a tool or prepare a metal sheet, a surface grinder is often the go-to machine.

Safety tip: Always check the wheel for cracks before use. A damaged wheel can shatter and cause serious injury. Do you inspect your grinding wheels regularly?

Cylindrical Grinders

Cylindrical grinders shape the outside of a workpiece, often cylindrical or round. They rotate the part against the grinding wheel for uniform results. This type is common in making engine parts or bearings where precision is critical.

Remember to secure the workpiece tightly to avoid slipping. Loose parts can cause accidents or poor finishes. How confident are you in your machine setup before starting?

Centerless Grinders

Centerless grinders remove material without holding the workpiece between centers. Instead, the part rests on a support blade and is guided by a regulating wheel. This machine is perfect for high-volume production of small parts like pins or rods.

Because the workpiece isn’t fixed, it’s important to maintain proper alignment. Misalignment can lead to uneven grinding or damage. Have you checked your machine’s alignment tools before beginning your task?

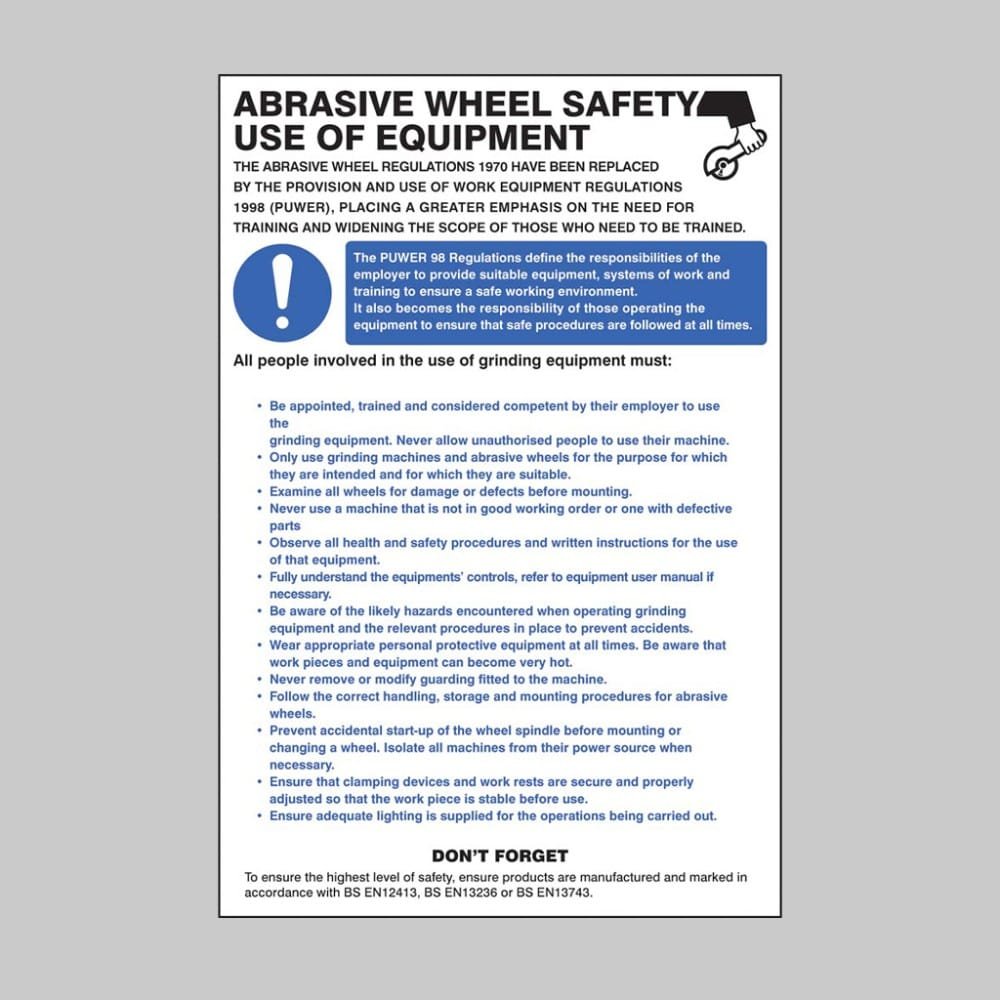

Credit: hsestore.co.uk

Common Hazards In Grinding Operations

Grinding operations carry several risks that can cause serious injury if not properly managed. Understanding the common hazards helps you stay alert and take the right safety measures. Let’s look closely at the dangers you face during grinding and how they can affect you.

Flying Particles And Sparks

Grinding produces tiny particles and sparks that fly off at high speed. These can cause eye injuries, burns, or skin irritation. You might think a quick glance or a simple shield is enough, but even small fragments can cause lasting damage.

Always wear safety goggles or a full-face shield to protect your eyes. Ensure your clothing covers exposed skin to prevent burns. Have you checked your protective gear lately to make sure it fits and is in good condition?

Wheel Breakage

Grinding wheels spin at very high speeds, and if they break, the fragments can fly with tremendous force. This can lead to severe cuts or blunt force injuries. Many accidents happen because wheels were cracked or worn out but still used.

Inspect wheels for cracks or damage before every use. Never exceed the recommended speed for the wheel. Think about the last time you checked your grinding wheel—could a hidden crack be a risk right now?

Noise And Vibration

Grinding machines generate loud noise and strong vibrations that can harm your hearing and hands. Prolonged exposure may cause hearing loss or conditions like hand-arm vibration syndrome (HAVS). You might not notice the damage until it’s too late.

Use ear protection like earmuffs or plugs every time you operate a grinder. Take regular breaks to reduce vibration exposure. Are you monitoring how long you use grinding equipment each day to protect your health?

Personal Protective Equipment

Grinding machines are powerful tools that can make your work easier and more efficient. However, they also come with significant risks if safety precautions aren’t followed. One of the most critical elements of staying safe is wearing the right personal protective equipment (PPE). Let’s break it down into key areas to ensure you’re fully protected while using a grinding machine.

Eye And Face Protection

Your eyes and face are highly vulnerable when operating a grinding machine. Sparks, debris, and even shattered abrasive wheels can cause severe injuries. Always wear safety goggles or a full-face shield designed for industrial work.

Check that your goggles fit snugly and are free from scratches or cracks. A scratched lens can distort your vision and increase the risk of accidents. If you’re using a face shield, remember it’s a secondary layer of protection—goggles should still be worn underneath.

Hearing Protection

Grinding machines often produce loud noises that can harm your hearing over time. You might not notice the damage immediately, but prolonged exposure can lead to permanent hearing loss. Use earplugs or earmuffs specifically rated for industrial noise levels.

Opt for comfortable hearing protection that you won’t mind wearing for extended periods. Disposable earplugs are convenient, but reusable earmuffs provide better durability. Pay attention to the noise reduction rating (NRR) to ensure adequate protection.

Gloves And Protective Clothing

Your hands are closest to the grinding machine, making them highly susceptible to injuries. Wear snug-fitting gloves that provide a good grip without being too bulky. Loose gloves can get caught in the machine, so avoid oversized or torn gloves.

Protective clothing such as aprons or long-sleeve shirts made from flame-resistant materials can shield your body from sparks and hot debris. Avoid wearing loose clothing, jewelry, or anything that could become entangled in the moving parts of the grinder. Always tuck in shirt tails and secure any loose ends before starting the machine.

Machine Setup Safety

Ensuring safety during the setup of a grinding machine is crucial. Proper machine setup minimizes risks and ensures smooth operation. By following key safety measures, you can protect both workers and equipment. This section highlights essential precautions to take during the setup process.

Inspecting The Grinding Wheel

Check the grinding wheel for cracks, chips, or other damage. A damaged wheel can break during operation, causing serious injuries. Tap the wheel gently with a non-metallic object to perform a “ring test.” A clear, metallic sound indicates the wheel is safe for use. Always use the right wheel type for the material being worked on.

Proper Mounting And Balancing

Secure the grinding wheel firmly on the machine spindle. Ensure the wheel is properly aligned and centered. Improper mounting can lead to vibrations and uneven grinding. Balance the wheel to avoid unnecessary strain on the machine. Use a balancing tool if needed to ensure smooth operation.

Guard Installation

Install machine guards to protect operators from flying debris. Ensure the guard covers the wheel and the spindle area. Adjust the guard to leave only the necessary part of the wheel exposed. Never operate the machine without properly installed guards. Guards reduce the risk of serious accidents.

Safe Operating Practices

Safe operating practices are essential for using grinding machines without injury. These practices reduce risks and ensure smooth work. Following clear guidelines helps protect both the operator and the equipment.

Always focus on safety from the moment you start the machine until you stop it. Proper habits prevent accidents and keep the workspace secure.

Starting And Stopping Procedures

Before starting, check the machine for any damage or loose parts. Make sure the grinding wheel is properly secured and guards are in place.

Turn the machine on smoothly and watch for unusual noises or vibrations. If anything seems wrong, stop immediately and inspect.

To stop, switch off the machine and wait for the wheel to stop completely before leaving the area. Never leave the machine running unattended.

Avoiding Distractions

Stay focused on the task while operating the grinder. Avoid talking, using phones, or other distractions nearby.

Distractions can cause mistakes leading to injury. Keep the work area clear of unnecessary people and clutter.

Concentrate on controlling the tool and maintaining steady movements during grinding.

Maintaining Correct Posture

Stand firmly with feet shoulder-width apart. This stance improves balance and control.

Keep your back straight and bend knees slightly. Avoid leaning too far forward or backward.

Hold the grinder firmly with both hands. Proper grip reduces fatigue and improves precision.

Credit: www.youtube.com

Maintenance And Inspection Checklist

Maintaining and inspecting grinding machines regularly ensures safe and efficient operation. A thorough checklist helps identify potential issues early. This reduces accidents and machine downtime. Follow these key steps to keep your grinding equipment in top condition.

Daily Equipment Checks

- Inspect guards and safety shields for proper placement.

- Check power cords and plugs for damage.

- Ensure emergency stops and switches work correctly.

- Look for unusual noises or vibrations during operation.

- Verify that all controls respond smoothly and accurately.

Wheel Condition Monitoring

- Examine wheels for cracks, chips, or uneven wear.

- Replace wheels showing signs of damage immediately.

- Perform a ring test to detect hidden cracks.

- Check wheel mounting for tightness and proper alignment.

- Balance wheels to prevent excessive vibration.

Lubrication And Cleaning

- Apply lubricant to moving parts as recommended by the manufacturer.

- Keep grinding surfaces free from dust and debris.

- Clean coolant nozzles and fluid reservoirs regularly.

- Remove buildup on guards, guards, and work areas.

- Use proper cleaning tools to avoid damaging components.

Emergency Response Measures

Grinding machines can be hazardous if safety precautions are overlooked. Even with the best practices, emergencies can still happen. Knowing how to respond quickly and efficiently can save lives and prevent further damage.

Handling Wheel Breakage

Wheel breakage is one of the most common grinding machine emergencies. If the wheel shatters during operation, stop the machine immediately and secure the area. Broken pieces can fly at high speeds, injuring anyone nearby.

Ensure everyone around knows the danger. Use safety barriers or caution tape to block off the area until the debris is cleared. Always inspect the grinding wheel before use to reduce the risk of breakage.

First Aid For Injuries

Accidents can lead to cuts, bruises, or worse. Keep a first aid kit near the grinding machine. It should include bandages, antiseptic, and gloves for treating wounds.

If someone gets hurt, clean the wound thoroughly and apply a bandage. For serious injuries, call emergency services immediately. Make sure all employees know basic first aid procedures.

Fire Safety Precautions

Grinding can produce sparks, increasing fire hazards. Always keep a fire extinguisher nearby, ideally one rated for electrical and flammable material fires. Ensure everyone knows how to use it.

Clear the workspace of flammable items like paper, cloth, or oil. If a fire starts, act quickly but stay calm. Evacuate the area and alert emergency services if the fire grows out of control.

Emergencies can escalate quickly, but preparation can make all the difference. Do you have the right measures in place to handle grinding machine accidents?

Training And Awareness

Training and awareness are key to safe grinding machine operation. Proper knowledge helps prevent accidents and injuries. Operators must understand machine functions and safety rules clearly. Consistent training builds confidence and skill. Regular updates keep safety knowledge fresh and relevant.

Operator Skill Development

Operators need hands-on practice and clear instructions. Training sessions should cover machine setup, operation, and shutdown. Teaching correct handling reduces the risk of mistakes. Skill development also includes learning to spot hazards early. Safety drills prepare operators for emergency situations.

Regular Safety Briefings

Safety briefings remind workers about key precautions. Short, frequent meetings help maintain awareness. Topics can include changes in procedures or new risks. Briefings encourage questions and sharing of safety tips. They create a culture where safety is a priority.

Updating Safety Protocols

Safety rules must evolve with new technology and findings. Review protocols regularly to address new hazards. Update training materials to reflect protocol changes. Communicate updates clearly to all operators and staff. Keeping protocols current prevents outdated practices and unsafe work.

Frequently Asked Questions

What Are The Basic Safety Precautions For Grinding Machines?

Always wear protective gear, ensure proper ventilation, and inspect the machine regularly. Follow manufacturer guidelines for safe operation and maintenance.

How To Check A Grinding Machine Before Use?

Inspect for damages, secure the workpiece, verify guards, and test the machine for proper functionality before starting.

Why Is Wearing Protective Equipment Important For Grinding?

Protective gear shields against flying debris, sparks, and dust, reducing the risk of injuries and respiratory issues.

Can Grinding Cause Serious Injuries If Precautions Are Ignored?

Yes, ignoring precautions can lead to cuts, burns, respiratory problems, and even severe injuries due to machine malfunctions.

Conclusion

Safety is key when using grinding machines. Always follow the checklist before starting work. Wear proper gear and keep your workspace clean. Check the machine for any damage or loose parts. Stay focused and never rush the job. These steps protect you and others around.

A safe work habit prevents accidents. Keep safety a daily priority for best results.