Construction Material Calculator Excel lets you start any project without the fear of miscalculating your materials. This powerful tool simplifies your planning process, saving both time and money.

That's exactly what a Construction Material Calculator in Excel can do for you. This practical tool is a game-changer, offering precision and efficiency at your fingertips. Whether you're a seasoned contractor or a DIY enthusiast, this calculator helps you make informed decisions, reducing waste and maximizing your budget.

Curious about how it can transform your project planning? Keep reading to discover how this Excel tool can revolutionize your construction endeavors, ensuring every ounce of material is accounted for and utilized effectively.

Benefits Of Using A Construction Material Calculator

Using a Construction Material Calculator brings many benefits to building projects. It helps save time, money, and effort. Accurate calculations improve the overall efficiency of construction work. The tool simplifies complex measurements and supports better decision-making.

Enhancing Measurement Accuracy

This accuracy helps maintain the quality of construction work, following ASTM material standards widely used in construction.

Reducing Material Waste

Calculators help order the right amount of materials needed. This reduces leftover waste and lowers disposal costs. Less waste means a cleaner, safer worksite. Efficient material use supports eco-friendly construction practices. It also improves project profitability by cutting unnecessary expenses.

Streamlining Project Planning

The calculator makes project planning faster and easier. It provides clear data for budgeting and scheduling. Builders can quickly compare different material needs and costs. This tool helps organize resources and manage timelines better. Project managers can focus more on other important tasks.

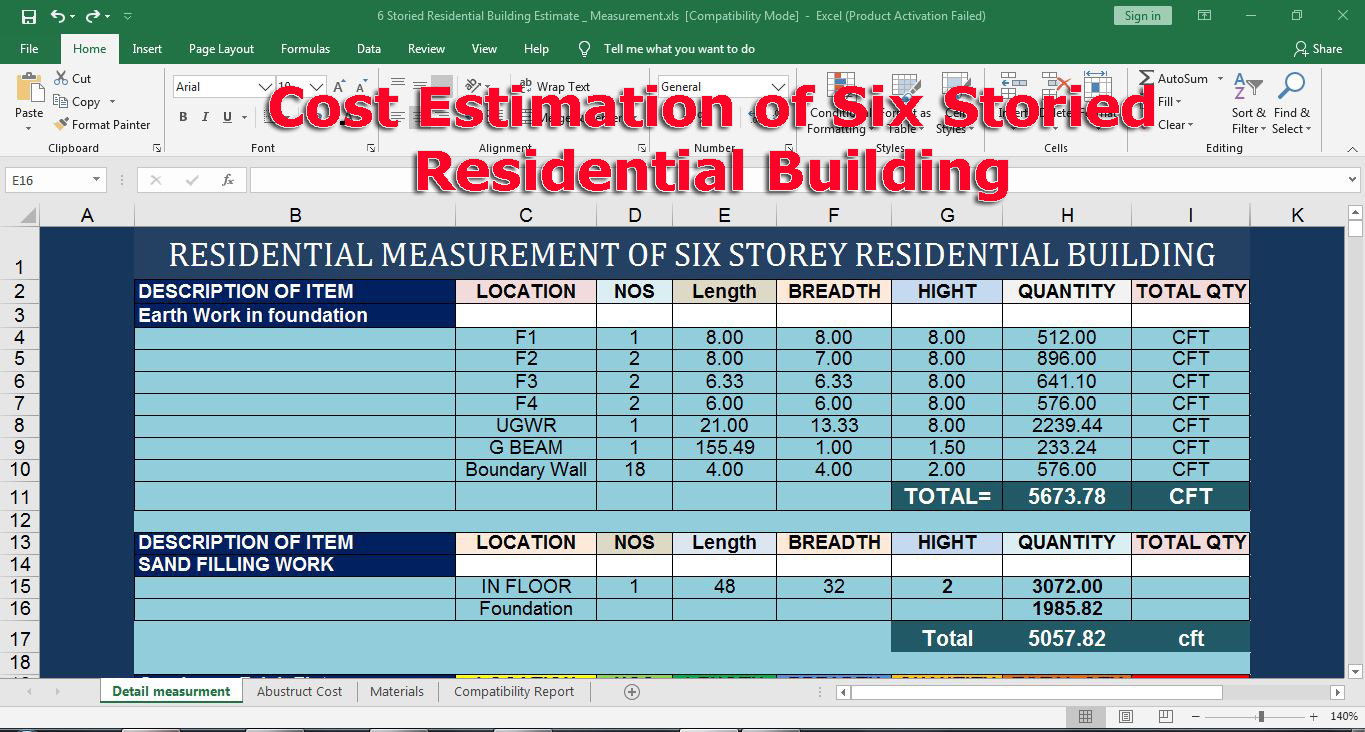

Credit: www.civilsite.info

Key Features Of Excel Calculators

Excel calculators for construction materials offer essential tools to simplify project planning. These calculators help estimate quantities, costs, and requirements quickly. They reduce errors and save time in preparing material lists. Understanding their key features shows why they are valuable for builders and contractors.

Customizable Templates

Templates in Excel calculators can be changed to fit specific needs. Users can add or remove rows and columns easily. This flexibility allows for adapting the calculator for different projects. It supports various materials like concrete, bricks, or steel. Custom templates ensure accurate calculations for unique job requirements.

Automated Calculations

Calculations happen automatically based on input data. Users enter measurements or quantities, and Excel does the rest. This feature reduces manual math errors and speeds up estimates. It updates totals instantly when numbers change. Automated formulas handle complex calculations with ease.

User-friendly Interface

Excel calculators offer simple and clear layouts. Input fields are easy to identify and use. Instructions or notes guide users through the process. The design avoids clutter, making navigation smooth. Even beginners can operate the tool without confusion.

Setting Up Your Construction Calculator In Excel

Setting up your construction material calculator in Excel is a smart move to keep your project organized and on budget. It lets you quickly estimate the amount of materials needed and track costs without relying on external tools. This hands-on approach gives you control and clarity, especially when project details change.

Inputting Project Details

Start by creating a clear section for your project details. Include fields like project name, location, and total area. These basics help you tailor calculations to your specific job.

Next, input cells are added for dimensions such as length, width, and height of the structures involved. Use simple labels so anyone can understand what values to enter. Remember, accuracy here saves time later.

- Project Name

- Site Address

- Building Dimensions (Length, Width, Height)

- Number of Floors

Creating Formulas For Material Quantities

Once your inputs are ready, it's time to build formulas that convert those numbers into material requirements. For example, to calculate concrete volume, multiply length by width and height.

You can use Excel functions like =PRODUCT()or simple multiplication operators. Set these formulas beside each material type to keep everything organized.

Think about all materials involved—cement bags, bricks, steel rods—and write formulas based on your project dimensions. This will let your sheet update material needs instantly when you change inputs.

MaterialFormulaDescription

Concrete (m³) = Length × Width × Height. Calculates volume needed for foundations or slabs.

Bricks (units) =Wall Area / Brick Area. Estimates the number of bricks based on the wall size

Steel Rods (kg) =Length Steel Density Determines steel weight for reinforcement.

Incorporating Cost Estimates

Now, assign costs to each material to get a budget overview. Create columns for unit price and total cost next to your quantity calculations.

Multiply the quantity by unit price to get total cost for each material. This step helps you spot which materials impact your budget most.

Consider adding a summary row that sums all material costs. This gives you a quick look at the overall expense and helps you adjust inputs to stay within budget.

Credit: www.etsy.com

Common Materials And Their Calculation Methods

Knowing how to calculate the quantity of common construction materials is key to managing your project budget and timeline effectively. Each material has its own measurement units and calculation methods. Getting these calculations right helps you avoid costly overbuying or delays caused by shortages.

Concrete And Cement

Concrete calculation usually starts with volume. You multiply the length, width, and depth of the area to get cubic meters or cubic feet.

For cement, you need to determine the mix ratio—like 1 part cement to 2 parts sand and 4 parts gravel. Then calculate the cement amount based on the total volume of concrete needed.

Using an Excel calculator, you can input your project dimensions and mix ratios to get precise quantities. Have you checked if your calculator adjusts for waste or variations in mix design?

Bricks And Blocks

Calculating bricks and blocks often involves counting the number of units per square meter or square foot of wall. Don’t forget to subtract openings like windows and doors.

Also, you should include extra bricks (usually 5-10%) to cover breakage and cutting. Excel templates can help you quickly estimate based on wall dimensions and brick size.

Think about how different brick sizes or mortar thickness might affect your calculation. Are you accounting for these variations in your current estimates?

Steel And Reinforcements

Steel quantity is usually calculated by weight. You measure the length of each steel bar and multiply by its weight per unit length.

For reinforcements, detailed drawings are essential to list all bars and their sizes. Excel sheets can sum these lengths and convert them to total weight for ordering.

Have you ever found a mismatch between calculated steel and what was actually used? Tracking this can improve your future estimates.

Wood And Lumber

Wood is typically measured in board feet or cubic meters. You calculate volume by multiplying the length, width, and thickness of each piece.

Remember to include allowances for waste and offcuts, especially if you’re cutting wood into various sizes. A well-set Excel calculator can help you manage these details efficiently.

Do you consider the type and grade of wood in your calculations? These factors can impact both quantity and cost significantly.

Tips To Maximize Efficiency With Excel Calculators

Excel calculators are valuable tools for managing construction materials, and efficiency improves project planning and reduces errors. Simple techniques can make these calculators more reliable and easier to use.

Focus on clear inputs, secure formulas, and current data. These tips help save time and avoid costly mistakes. Small changes can create a big impact on workflow.

Using Data Validation And Drop-down Lists

Data validation limits input to specific values. This reduces mistakes in entering material types or units. Drop-down lists offer users easy choices without typing.

- Choose a cell or range for input.

- Go to Data > Data Validation in Excel.

- Select List and enter possible options.

- Users pick from the List instead of typing.

This keeps data consistent across the Sheet. It also speeds up data entry and reduces confusion.

Protecting Formulas From Accidental Changes

Formulas calculate quantities and costs. Accidental edits can cause errors. Protect these cells to keep calculations accurate.

- Select all cells and unlock them.

- Lock only the cells with formulas.

- Use Review > Protect Sheet to enable protection.

- Set a password if needed for safety.

This prevents users from changing formulas by mistake. It maintains the integrity of your calculator.

Regularly Updating Material Prices

Material costs often fluctuate. Keep prices current for accurate budgeting. Outdated prices lead to wrong estimates and overspending.

- Create a dedicated price list tab.

- Update prices monthly or as needed.

- Link price cells to the main calculator.

- Highlight cells that need regular updates.

Accurate pricing helps track expenses and plan better. It supports smarter decision-making during construction projects.

Credit: pazera-software.com

Troubleshooting And Avoiding Common Errors

Using a Construction Material Calculator in Excel can save you time and reduce waste, but errors can sneak in if you're not careful. Troubleshooting and avoiding common mistakes ensures your calculations stay accurate and reliable. Let’s look at key areas where errors often appear and how you can fix or prevent them.

Handling Formula Mistakes

Formula errors are one of the most frequent issues in Excel calculators. A misplaced parenthesis or a wrong cell reference can throw off your entire calculation.

Double-check your formulas by breaking them down into smaller parts. Use Excel’s “Evaluate Formula” tool to see each calculation step and identify where it goes wrong.

Have you ever copied a formula down a column only to find some cells showing strange results? This often happens because of relative cell references. Lock important cells using the dollar sign ($) to keep references fixed.

Managing Unit Conversion Issues

Unit mismatch can cause huge errors, especially when mixing feet, inches, meters, or kilograms. Always confirm that your input units match the expected units in the formula.

One trick is to create a separate conversion table within your Excel sheet. This lets you standardize units before feeding them into your calculator, reducing confusion.

Ask yourself: Are you sure all your measurements are in the same unit system? A small oversight here can lead to ordering twice the amount of material or not enough.

Dealing With Incomplete Data

Missing values can break formulas or produce misleading results. Instead of leaving blank cells, use placeholders like zero or “N/A” and adjust your formulas to handle these cases.

Excel functions like IFERROR or ISBLANK can help you manage incomplete data gracefully. They prevent errors from stopping your calculations and alert you to missing inputs.

Consider adding data validation rules to restrict input types or require all necessary fields before allowing calculations. This proactive step reduces human error before it happens.

Integrating Excel Calculators With Other Tools

Integrating your construction material calculator in Excel with other tools can save you time and reduce errors. By connecting Excel with project management software, exporting data for reports, or using mobile versions, you make your workflow smoother. You’ll find it easier to track materials, manage budgets, and make quick decisions on-site.

Linking With Project Management Software

Linking Excel calculators with project management software lets you sync material calculations directly with your project timeline and budget. Tools like Microsoft Project or Trello can pull data from Excel sheets to update progress or costs automatically.

This connection reduces duplicate data entry and helps you keep everyone on the same page. Imagine updating material needs in Excel and instantly seeing how it affects your project schedule in real time. How much time could you save by avoiding manual updates?

Exporting Data For Reporting

Exporting your Excel data into formats like CSV or PDF makes reporting easier and more professional. You can create detailed reports for clients or stakeholders showing exact material quantities and costs.

These reports help you back up your estimates and project status with clear, organized data. What would it mean for your credibility if you could deliver precise, up-to-date reports without extra effort?

Using Mobile Versions For On-site Calculations

Using mobile versions of Excel or compatible apps means you can perform material calculations right on the construction site. This flexibility lets you adjust quantities quickly if plans change or unexpected issues arise.

Having your calculator on a tablet or smartphone means no more waiting to get back to the office for updates. How often have on-site changes caused delays that could have been avoided with faster calculations?

Frequently Asked Questions

What Is A Construction Material Calculator Excel?

A Construction Material Calculator Excel is a spreadsheet tool. It helps estimate material quantities for building projects. It saves time and reduces calculation errors. Users input project dimensions, and the Sheet calculates required materials accurately.

How Does Construction Material Calculator Excel Save Costs?

This calculator prevents material wastage by providing precise estimates. It helps buy only the needed quantities, avoiding excess purchases. Accurate calculations reduce project delays and rework. Overall, it optimizes budget management during construction.

Can Beginners Use the Construction Material Calculator Excel Easily?

Yes, it is user-friendly and requires no advanced skills. Most templates come with instructions and pre-set formulas. Beginners can input measurements directly to get results. It simplifies complex calculations for anyone in construction.

Which Materials Can Be Calculated Using This Excel Tool?

Common materials include cement, sand, gravel, bricks, and steel. Users can customize sheets to add more materials. It supports calculations for concrete, plaster, and masonry work. The tool adapts to various construction needs efficiently.

Conclusion

Using a construction material calculator in Excel saves time and reduces errors. It helps you plan materials with clear numbers. This tool makes budgeting easier and avoids waste. You get quick results without complex math. Anyone can use it, even with basic Excel skills.

Try this calculator to keep your project on track and cost-effective. Simple, fast, and useful for every builder.