Are you wondering if mechanical fasteners are the right choice for your project? You’re not alone.

Choosing the correct fastening solution is crucial for the success of any assembly or construction task. Mechanical fasteners, like screws, bolts, and nuts, are popular for their reliability and versatility. However, with so many options available, it can be challenging to determine if they are the best fit for your specific needs.

We’ll explore the benefits and potential drawbacks of mechanical fasteners, helping you make a more informed decision. By the end, you’ll have a clearer understanding of whether these trusty components align with your goals, ensuring your project not only stands firm but also stands out. Ready to discover more? Let’s dive in!

Types Of Mechanical Fasteners

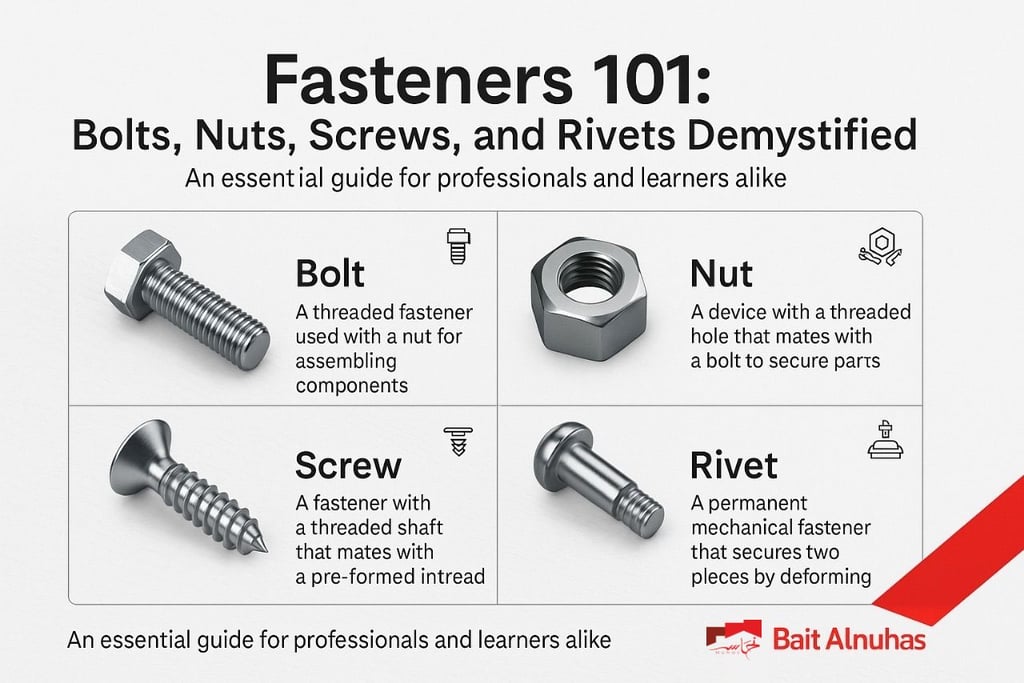

Mechanical fasteners are essential in various industries. They join parts securely and are easy to remove and replace. Different types of mechanical fasteners serve different purposes. Here, we explore some common types to help you choose the right one for your needs.

Bolts And Screws

Bolts and screws are versatile and widely used. They come in various sizes and shapes. Bolts often pair with nuts to hold objects together. Screws, on the other hand, have threads that cut into the material. This makes them ideal for wood and plastic applications. They provide strong, durable connections that are easy to undo.

Nuts And Washers

Nuts are crucial in fastening systems. They secure bolts and screws, providing stability. Different types of nuts offer varying levels of strength and flexibility. Washers distribute the load of a fastener. They prevent damage and ensure a tight fit. This combination enhances the durability and reliability of mechanical connections.

Rivets And Pins

Rivets are permanent fasteners. They are ideal for applications where removal is not needed. They join materials like metal, leather, and plastic effectively. Pins, such as cotter pins, serve as temporary fasteners. They are easy to install and remove. This makes them suitable for applications requiring frequent assembly and disassembly.

Advantages Of Mechanical Fasteners

Mechanical fasteners are a staple in many industries, offering a plethora of advantages that make them a preferred choice for many applications. Whether you’re assembling furniture or constructing a building, these fasteners provide a reliable and versatile solution. But what makes them so advantageous? Let’s delve into the benefits that make mechanical fasteners a standout choice.

Ease Of Installation

One of the most significant advantages of mechanical fasteners is their ease of installation. You don’t need specialized training or expensive equipment to use them effectively. With basic tools, you can quickly secure components together. This simplicity saves time and reduces the potential for errors during assembly. Have you ever tried to assemble a piece of furniture with only a screwdriver? Mechanical fasteners make it possible.

Reusability

Mechanical fasteners are often reusable, allowing you to disassemble and reassemble components without compromising their integrity. This feature is particularly beneficial in situations where adjustments or repairs are necessary. Imagine having to change a component in a complex setup. With mechanical fasteners, you can easily swap parts without damaging the surrounding material. Their reusability extends the lifecycle of products and supports sustainable practices.

Cost-effectiveness

The cost-effectiveness of mechanical fasteners is another compelling reason to choose them. They are generally inexpensive compared to other fastening methods, such as welding or adhesives. The savings don’t just stop at initial purchase; their ease of installation and reusability further reduce long-term costs. Are you looking for a budget-friendly solution for your project? Mechanical fasteners might be the answer.

Limitations Of Mechanical Fasteners

Mechanical fasteners can cause material stress and are less effective in dynamic environments. They may require regular maintenance to ensure structural integrity. Additionally, they might not provide the same level of strength as welded or bonded joints.

Mechanical fasteners are a staple in construction and manufacturing, providing a reliable way to connect components. However, they come with limitations that might impact your project’s long-term success. Understanding these limitations can help you make better decisions when choosing fastening methods.Potential For Loosening

Mechanical fasteners can loosen over time, especially in applications subject to vibrations or dynamic loads. This can lead to structural instability and increased maintenance costs. Think about the last time you had to tighten screws on a wobbling table. It’s a minor inconvenience at home, but in industrial applications, it could mean compromised safety or equipment failure. So, how often do you check the integrity of fasteners in critical applications?Corrosion Risks

Corrosion is a silent enemy of mechanical fasteners. In environments with high humidity or exposure to chemicals, fasteners can rust, weakening their hold. This is particularly concerning in outdoor or marine applications. Have you ever noticed rust on screws and bolts around your home? Imagine that in a more demanding setting—it could lead to catastrophic failures. Choosing the right material and protective coatings can mitigate these risks.Weight Considerations

Mechanical fasteners add weight to your structure, which might not be ideal for lightweight applications. This is crucial in industries like aerospace, where every gram counts. Consider how adding dozens of bolts could affect the overall weight of a lightweight drone or aircraft component. Are there alternative fastening methods that offer the strength you need without the added weight? Exploring options like adhesives or advanced composite materials might offer a solution.

Credit: firstmold.com

Comparison With Adhesive Bonding

Mechanical fasteners offer strong connections ideal for heavy loads and easy repairs. Adhesive bonding provides a seamless appearance and distributes stress evenly. Each method excels in specific applications, depending on the demands for strength, aesthetics, and durability.

The debate over mechanical fasteners versus adhesive bonding is a frequent topic among engineers, DIY enthusiasts, and manufacturers alike. Each method offers unique advantages that make them suitable for different applications. Have you ever found yourself wondering whether screws or glue are the better choice for your project? Let’s dive into a comparison of these two methods to help you make an informed decision.Strength And Durability

Mechanical fasteners, like screws and bolts, provide immediate strength. Once installed, they offer a secure hold that can withstand significant force. Imagine building a bookshelf; the stability you get with screws is hard to match. Adhesive bonding, on the other hand, distributes stress evenly across the bonded area. This can lead to greater durability in certain situations. Think about assembling lightweight structures or materials that might suffer under concentrated pressure. Which method aligns with your project’s needs for strength and longevity? Consider the forces your structure will face over time.Application Process

Mechanical fasteners are straightforward. You drill a hole, insert a screw, and tighten it. The process is quick and allows for easy dismantling if adjustments are needed. Ever had to fix a wobbly chair? Screws make it a breeze. Adhesive bonding requires precision and patience. You must ensure surfaces are clean and apply the glue correctly. The curing time can be a drawback if you’re in a hurry. However, adhesives can seamlessly join irregular surfaces. Does your project require speed or precision? Your timeline and design complexity might dictate your choice.Environmental Impact

Mechanical fasteners are reusable, making them a more sustainable option. You can disassemble and repurpose them, reducing waste. Have you ever repurposed old screws from a broken gadget? It’s a small step towards sustainability. Adhesives may contain chemicals that could be harmful to the environment. Disposal can be challenging, especially with non-biodegradable options. Yet, newer eco-friendly adhesives are emerging as alternatives. Are you prioritizing environmental impact in your project? The choice between screws and glue can reflect your values in sustainability. As you weigh these factors, remember that the best choice depends on your specific needs and circumstances. What works for one project might not suit another.Applications In Various Industries

Mechanical fasteners are the unsung heroes behind the scenes, holding together everything from cars to skyscrapers. They’re versatile, reliable, and crucial in various industries. But do they fit all applications seamlessly? Let’s dive into how these fasteners play pivotal roles across different sectors.

Automotive And Aerospace

In the automotive industry, mechanical fasteners are like the glue holding together the vehicle’s intricate puzzle. From securing engine components to assembling body panels, these fasteners ensure durability and safety. Imagine the chaos on a racetrack if these fasteners failed—every bolt matters.

Aerospace applications demand even higher precision and reliability. Fasteners here withstand extreme conditions, from the pressure of high-speed flights to the temperatures of outer space. Your last flight might have seemed smooth, but it was a symphony of fasteners working behind the scenes.

Construction And Infrastructure

In construction, mechanical fasteners are the backbone of stability. They hold together steel beams, wooden frameworks, and concrete forms. Every skyscraper you marvel at owes its sturdiness to these fasteners.

Consider bridges—fasteners maintain their integrity against natural forces like wind and water. As you drive across, you trust in the hidden strength of these tiny components. They are a critical part of ensuring safety in our everyday infrastructure.

Consumer Electronics

Consumer electronics rely on mechanical fasteners for both structure and functionality. Your smartphone, laptop, and television all contain these fasteners in various forms. Without them, gadgets would fall apart, leaving you disconnected.

Ever dropped your phone and had it survive? Thank those internal fasteners for keeping it intact. They provide the resilience needed to withstand daily wear and tear, ensuring your devices stay functional and reliable.

Innovations In Mechanical Fasteners

Mechanical fasteners offer reliable connections and easy assembly. They adapt well to diverse applications, making them a smart choice. Their versatility and cost-effectiveness ensure they meet various industry needs efficiently.

Innovations in mechanical fasteners are reshaping industries with new designs and materials. These advancements aim to enhance efficiency, sustainability, and functionality. As you explore these innovations, consider how they might fit into your projects or business needs.Smart Fasteners

Imagine fasteners that can communicate. Smart fasteners integrate sensors and connectivity features, offering real-time data on tension and integrity. This technology can prevent failures before they occur, saving you time and resources. Smart fasteners are particularly useful in critical applications such as aerospace and automotive. They provide valuable insights into the health of a structure, ensuring safety and reliability. Are you ready to embrace the future of fastening with these intelligent solutions?Eco-friendly Materials

The demand for sustainable solutions is driving innovation in fastener materials. Eco-friendly fasteners are made from recycled or biodegradable materials, reducing environmental impact. Using these materials can enhance your brand’s commitment to sustainability while maintaining performance. Consider fasteners crafted from bioplastics or recycled metals. They offer durability comparable to traditional materials but with a smaller carbon footprint. How can choosing eco-friendly fasteners align with your values and goals?Advanced Coatings

Advanced coatings are revolutionizing fastener durability and performance. These coatings protect against corrosion, wear, and temperature extremes. By extending the lifespan of fasteners, they reduce maintenance costs and downtime. Think about fasteners with self-healing coatings that repair scratches and prolong service life. Such innovations can improve reliability in demanding environments. What benefits could advanced coatings bring to your projects?Choosing The Right Fastener

Mechanical fasteners can be an excellent choice for various projects. They provide reliable strength and easy installation. Choosing the right type ensures durability and efficiency, making them suitable for many applications.

Choosing the right fastener is essential for any project. It ensures the durability and safety of the assembly. Mechanical fasteners come in various types. Each type suits different needs and conditions. Understanding how to choose the right fastener can save time and money. Below are key factors to consider.Material Compatibility

The materials being joined must match the fastener material. This prevents corrosion and ensures a strong bond. For example, use stainless steel fasteners with stainless steel parts. Dissimilar metals can cause galvanic corrosion. Always check the material specifications before choosing.Load Requirements

Know the load your fastener will bear. Different fasteners handle different loads. Light loads may only need screws or nails. Heavy loads might require bolts or anchors. Always calculate the load accurately. This ensures the fastener performs well under stress.Environmental Conditions

Consider the environment where the fastener will be used. Outdoor conditions demand rust-resistant materials. Humid or salty areas need corrosion-resistant fasteners. Temperature changes can affect material expansion. Choose fasteners that withstand environmental conditions. This ensures longevity and reliability.

Credit: www.assemblymag.com

Credit: baitalnuhas.com

Frequently Asked Questions

What Are Mechanical Fasteners Used For?

Mechanical fasteners are used to securely join two or more components. They provide strong and durable connections in various applications, including construction, automotive, and electronics. These fasteners come in different forms like screws, bolts, and nuts, offering versatility for different materials and structures.

How Do Mechanical Fasteners Work?

Mechanical fasteners work by creating friction or tension between components. They lock parts together using threads, pressure, or interlocking designs. Their effectiveness depends on the material, design, and application. Proper installation ensures strong and reliable connections, reducing the risk of loosening or failure.

Are Mechanical Fasteners Reliable?

Mechanical fasteners are reliable when chosen and installed correctly. They offer strong and durable connections for various applications. Their reliability depends on the material, design, and installation. Regular maintenance and inspection ensure their effectiveness and longevity in critical applications.

What Materials Are Suitable For Mechanical Fasteners?

Mechanical fasteners are suitable for materials like metal, plastic, and wood. Their design and material compatibility ensure secure connections. Different types of fasteners are available for specific materials, providing versatility in applications. Proper selection ensures optimal performance and durability.

Conclusion

Mechanical fasteners offer practical benefits. They provide strength and reliability. Easy to install, they save time. They are adaptable to various materials. Costs can vary, but often budget-friendly. Consider the environment they will be used in. Think about the load they need to bear.

Evaluate the ease of maintenance. Compare alternatives to make the best choice. Mechanical fasteners can be an excellent option. Choose wisely based on your project needs. This decision impacts the quality and durability. Make sure it aligns with your goals.