Have you ever struggled to keep panels securely fastened in your projects? You’re not alone.

Understanding the right panel fasteners can make all the difference in ensuring your work is both sturdy and reliable. Imagine the peace of mind that comes with knowing your panels are securely fixed, leaving you free to focus on other aspects of your project.

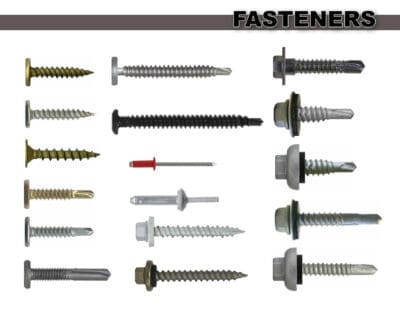

You’ll discover the different types of panel fasteners that can transform your tasks from frustrating to seamless. From screws to rivets and everything in between, we’ll guide you through the options, helping you choose the perfect fastener for your needs. Whether you’re a DIY enthusiast or a seasoned professional, unlocking the secrets to these fasteners will enhance your efficiency and confidence. Stay with us as we delve into the world of panel fasteners—your projects will thank you!

Credit: baitalnuhas.com

Panel Fastener Basics

Panel fasteners are essential in various industries. They join panels securely while allowing easy access. These fasteners come in different types, each serving a unique purpose. Understanding the basics of panel fasteners can help in choosing the right type for your needs.

Types Of Panel Fasteners

Panel fasteners come in several varieties. Each type offers specific advantages.

- Quarter-Turn Fasteners

- Push-Button Fasteners

- Screw-On Fasteners

- Snap-On Fasteners

Quarter-turn fasteners are simple to use. They require a 90-degree turn to lock or unlock. This makes them ideal for quick access panels.

Push-button fasteners offer convenience. Press the button to release or secure them. They’re great for frequent panel access.

Screw-on Fasteners

Screw-on fasteners provide a secure hold. They require a tool for installation. This makes them suitable for permanent applications.

Snap-on Fasteners

Snap-on fasteners are easy to install. They snap into place without tools. Perfect for lightweight panels.

Consider panel weight and access frequency. Select a fastener that meets these needs. This ensures efficiency and safety.

Quarter-turn Fasteners

Quarter-turn fasteners are popular panel fasteners for securing panels quickly. They include Dzus, Camloc, and Airloc types, each offering unique advantages for various applications.

Quarter-turn fasteners are a unique breed in the world of panel fasteners. Their defining feature is the simplicity and speed with which they can be operated. Imagine needing only a quick twist—literally a quarter-turn—to secure or release a panel. This ease of use makes them particularly appealing in scenarios where time is of the essence or frequent access is required. But how do they work, and where can you find them in action?Mechanism And Design

Quarter-turn fasteners operate on a straightforward mechanism. They consist of a stud that aligns with a receptacle. When you turn the stud 90 degrees, it locks into place, securing the panel. This quick motion is facilitated by the design, often featuring a cam or a slotted head that provides the necessary locking strength. Their design varies, with some models offering a tool-less operation, allowing you to use fingers for a quick twist. Others may require a simple tool for added security. The compact design makes them suitable for tight spaces where traditional fasteners might be cumbersome.Common Applications

These fasteners are a favorite in industries where panels need regular removal or adjustments. Think about aerospace applications where rapid access to systems is crucial. They are also prevalent in automotive sectors, simplifying the assembly and disassembly of components. Beyond industrial use, quarter-turn fasteners are handy in consumer electronics where quick assembly is a bonus. Have you ever wondered why the back panel of your device is so easy to remove? Quarter-turn fasteners could be the reason. Consider using quarter-turn fasteners in your DIY projects. They offer a practical solution for creating modular designs that are easy to assemble and disassemble. Where might you find them simplifying your life?Quick-release Fasteners

Quick-release fasteners come in various types, including quarter-turn, push-pull, and cam-lock. Each offers unique benefits for securing panels efficiently. Choosing the right type depends on your specific application needs and ease of use.

Quick-release fasteners are a game-changer in the world of panel fastening. These innovative fasteners allow for swift and easy attachment and detachment, making them ideal for situations where frequent access is required. Think about how often you need to remove a panel quickly and easily; that’s where quick-release fasteners shine.Advantages And Uses

Quick-release fasteners offer significant advantages. They save time by reducing the effort required to remove panels. This makes them perfect for industries like aerospace and automotive, where rapid access to components is crucial. They are also user-friendly, which means anyone can use them without needing special tools. Whether you’re maintaining a race car or working on an aircraft, these fasteners provide reliability and efficiency.Installation Process

Installing quick-release fasteners is straightforward.- First, align the fastener with the panel and the frame.

- Secure the fastener by engaging it through the designated holes.

- Ensure it is tightly locked in place to prevent any movement.

Push-button Fasteners

Push-button fasteners are versatile tools used in various applications. Types of panel fasteners include snap-in, quarter-turn, and threaded styles. Each type offers unique features for efficient assembly and disassembly of panels.

Push-button fasteners offer a quick and efficient way to secure panels. They are popular for their ease of use and time-saving qualities. These fasteners require just a simple push to lock or release, making them ideal for applications where speed is crucial. Their versatility allows them to be used in various industries, from automotive to electronics.Features And Benefits

Push-button fasteners are designed for convenience. They eliminate the need for tools, providing a straightforward installation process. This feature reduces downtime and labor costs. Their compact design ensures minimal space usage, making them ideal for tight spots. – Quick Installation: No tools needed, saving time. – Space Efficient: Compact design fits small areas. – Cost-Effective: Reduces labor and tool expenses. These fasteners are durable, maintaining their integrity even under frequent use. Their robust construction ensures longevity, providing reliable performance.Industry Applications

Push-button fasteners are used across various sectors. In the automotive industry, they secure panels inside vehicles, allowing quick access for maintenance. Electronics use these fasteners to attach components within devices, facilitating easy assembly and repair. – Automotive: Ideal for interior panel installation. – Electronics: Used for assembling device components. – Aerospace: Ensures secure fastening in aircraft cabins. These fasteners are favored in industries where speed and reliability are critical. Their adaptability makes them a preferred choice for many applications.Threaded Fasteners

Panel fasteners come in various types, including push-in, snap-in, and quarter-turn fasteners. These fasteners securely attach panels and are essential in industries like automotive and electronics. Each type offers unique benefits, ensuring panels are held firmly in place.

Threaded fasteners are the unsung heroes in the world of panel assembly. They play a crucial role in securing panels together, ensuring stability and durability in various applications. If you’ve ever assembled furniture or tinkered with machinery, you’ve likely encountered these versatile components. Their ability to create a strong hold makes them indispensable in both DIY projects and professional settings.Types And Varieties

Threaded fasteners come in a plethora of shapes and sizes, catering to different needs. Some common types include screws, bolts, and studs. Each serves a unique purpose depending on the project requirements. Screws, for instance, are typically used for wood or plastic panels, where they can easily create a secure fit. Bolts, on the other hand, are perfect for metal panels, providing a robust hold through nuts and washers. Studs offer a more permanent solution, often used in automotive or industrial applications where a fixed stud is essential. The variety doesn’t stop there. You’ll find these fasteners in different materials like steel, brass, or even nylon, each offering distinct advantages such as corrosion resistance or lightweight properties.Typical Uses

Threaded fasteners are incredibly versatile, finding their way into countless applications. Have you ever put together a flat-pack furniture piece? Those screws that hold everything together are threaded fasteners. In construction, these fasteners are pivotal in framing, ensuring everything is securely in place. They also hold machinery parts together, providing the stability needed for operation. Even in electronics, threaded fasteners are used to assemble components and keep them safe from external disturbances. Their ability to be easily removed and replaced makes them a favorite for projects requiring regular adjustments. Have you ever considered how much easier your life would be without the hassle of loose panels? Threaded fasteners might be the solution you’re looking for.Captive Fasteners

Captive fasteners come in various types such as snap-in, push-in, and screw-in panel fasteners. Each type offers unique benefits for securing panels effectively. These fasteners ensure panels stay in place while allowing easy maintenance access.

Captive fasteners are essential components in many industries. They stay attached to their parent material. This means they won’t get lost during maintenance or repairs. They offer convenience and efficiency. Captive fasteners are available in various designs to suit different applications.Safety And Security

Captive fasteners enhance safety by staying in place. This reduces the risk of loose parts causing harm. They also improve security by preventing tampering or unauthorized removal. Industries like aerospace and electronics rely on these fasteners. They ensure components remain intact during operation. Their reliability makes them a popular choice for critical applications.Common Installations

Captive fasteners find use in various installations. They are common in electronic enclosures and panels. These fasteners are also used in machinery, providing easy access for maintenance. They help in assembling furniture, ensuring components stay together. In automotive applications, they secure parts while allowing easy removal. Their versatility makes them suitable for many projects.Panel Fastener Materials

When selecting panel fasteners, one of the most crucial considerations is the material from which they are made. The material dictates the fastener’s strength, durability, and suitability for various environments. Whether you’re dealing with heavy-duty machinery or lightweight panels, choosing the right material can make all the difference.

Metal Options

Metal fasteners are renowned for their strength and reliability. Common choices include steel, stainless steel, and aluminum. Steel fasteners are often used in heavy-duty applications due to their high tensile strength.

Stainless steel offers excellent corrosion resistance, making it ideal for outdoor or marine environments. Meanwhile, aluminum fasteners are lightweight yet strong, perfect for applications where weight is a concern. Have you ever noticed how your aluminum ladder feels sturdy yet easy to lift? That’s the magic of aluminum fasteners in action!

Non-metal Alternatives

Non-metal fasteners provide unique benefits where traditional metals might fall short. Plastic fasteners, for instance, are corrosion-resistant and non-conductive, suitable for electrical applications. They also come in an array of colors, offering aesthetic flexibility for visible installations.

Composite materials are another interesting option. They combine the benefits of different materials, such as strength and corrosion resistance, providing a balanced solution for various applications. Imagine a fastener that can withstand harsh chemicals without rusting—that’s what composites bring to the table. Which material aligns best with your project needs?

Credit: www.facebook.com

Choosing The Right Fastener

Choosing the right fastener for your panels can feel like selecting a tool from a vast toolbox. Each fastener type offers unique benefits, and making the right choice depends on various factors. Understanding these elements ensures your panels remain secure, durable, and aesthetically pleasing. Your decision should align with the specific requirements of your project, considering factors such as material compatibility, load-bearing capacity, and environmental influences.

Considerations For Selection

When selecting a panel fastener, think about the material of the panel and the substrate it will attach to. Compatibility is crucial to prevent damage and ensure a secure fit. Imagine the ease of installation—do you need a fastener that requires specialized tools, or would a simple snap-fit suffice?

Consider the aesthetics, too. Do you want the fastener to blend seamlessly with the panel or stand out as a design feature? Each choice impacts the overall look and feel of your project.

Also, reflect on the functional requirements. Will the fastener need to support heavy loads or withstand regular adjustments? Your answers will guide you to the right option.

Environmental Factors

Environmental conditions play a significant role in fastener selection. If your panels are outdoors, exposure to weather elements like rain, wind, and UV rays can affect fastener performance. Consider corrosion-resistant materials like stainless steel or coated metals for durability.

Temperature fluctuations can also impact fasteners. Extreme heat or cold may cause expansion or contraction, affecting the panel’s integrity. Choosing a fastener that can withstand these changes ensures longevity.

Think about humidity levels, especially for indoor panels. Excess moisture can lead to rust or degradation. Opt for fasteners designed to endure these conditions for peace of mind and sustained functionality.

Credit: southco.com

Frequently Asked Questions

What Are Panel Fasteners Used For?

Panel fasteners secure panels, components, or enclosures in various applications. They provide easy assembly and disassembly. These fasteners are common in automotive, electronics, and construction industries. Their design ensures quick installation without tools. They help improve efficiency and reduce maintenance time.

How Do Quarter-turn Fasteners Work?

Quarter-turn fasteners lock and unlock with a 90-degree turn. They offer quick access to panels and components. These fasteners are vibration-resistant and secure. They’re ideal for applications requiring frequent access. Their design ensures reliable and efficient fastening.

What Is The Purpose Of Push-in Fasteners?

Push-in fasteners secure panels without tools. They’re easy to install by simply pushing into place. These fasteners are reusable and cost-effective. They provide a strong hold and are suitable for lightweight applications. Push-in fasteners reduce assembly time and enhance efficiency.

Where Are Captive Panel Fasteners Used?

Captive panel fasteners are used in applications requiring permanent attachment. They prevent loss of fasteners during maintenance. Common in electronics and aerospace industries, they ensure reliability. These fasteners offer quick access and ease of use. Their design enhances safety and reduces downtime.

Conclusion

Panel fasteners come in many shapes and sizes. Each type serves a unique purpose. They ensure panels stay secure and aligned. Choosing the right fastener is crucial. It affects the panel’s performance and longevity. Think about the material and load requirements.

Consider ease of installation too. Explore options like rivets, screws, and clips. Each has distinct features and benefits. Understand your project needs for the best choice. Proper selection leads to efficient and durable panel setups. Invest time in understanding fasteners.

It pays off in the long run. Quality panels rely on the right fasteners.