When developing an electrical safety program, your main goal is to protect everyone who works with or around electricity. You might think it’s just about following rules, but it’s much more than that.

A strong program keeps accidents away, saves lives, and prevents costly downtime. If you want to create a plan that truly works, you need to know what steps matter most. Keep reading, and you’ll discover practical tips that make your workplace safer and give you peace of mind.

Don’t leave safety to chance—take control now.

Assessing Workplace Risks

Assessing workplace risks is the foundation of any effective electrical safety program. It helps you understand where dangers lie and how serious they might be. This knowledge lets you focus your efforts where they matter most, keeping your team safe and your operations running smoothly.

Identifying Electrical Hazards

Start by walking through your workplace with a sharp eye. Look for exposed wiring, damaged insulation, overloaded circuits, and wet areas near electrical equipment. Don’t forget to check less obvious spots like inside control panels or behind heavy machinery.

Ask yourself: Are there tools or appliances that spark or overheat? Are extension cords used as permanent wiring? Spotting these hazards early helps prevent accidents before they happen.

Evaluating Risk Levels

Not all electrical hazards carry the same level of risk. Consider factors like the voltage involved, frequency of exposure, and potential consequences of an incident. For instance, a loose wire near a water source poses a higher risk than one tucked safely away in a dry area.

Use a simple risk matrix to rate hazards as low, medium, or high risk. This makes it easier to decide which issues need immediate attention and which can be monitored over time.

Prioritizing Safety Measures

Once risks are clear, decide which safety measures will be most effective. High-risk hazards might require installing circuit breakers, adding protective covers, or conducting specialized training. Lower-risk issues could be managed with regular inspections or housekeeping improvements.

Think about your resources and the impact on daily work. What can you realistically implement now to reduce the biggest dangers? Your safety program should grow step-by-step, focusing on the biggest threats first.

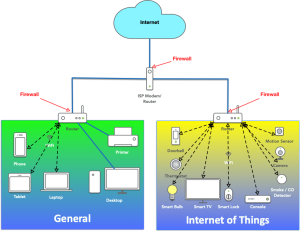

Credit: www.academia.edu

Setting Safety Policies

Setting safety policies is the foundation of any effective electrical safety program. Clear policies guide everyone’s actions and set the tone for a culture that prioritizes safety. Without well-defined policies, even the best training and equipment can fall short.

Defining Safety Objectives

Start by pinpointing what your safety program must achieve. These objectives should be specific, measurable, and relevant to your workplace’s unique risks. For example, reducing electrical accidents by a certain percentage within a year gives your team a clear target to aim for.

Think about the critical outcomes you want. Is it preventing shocks, avoiding fires, or improving emergency response? Defining these goals early helps you focus resources where they matter most.

Establishing Rules And Procedures

Your policies need to spell out exactly what behaviors are required and prohibited. Clear rules eliminate guesswork and help employees understand their responsibilities. For instance, a rule might require lockout/tagout procedures before any electrical maintenance.

Procedures should detail step-by-step actions for safely handling electrical tasks. Writing these down ensures everyone follows the same process and reduces risks. Have you ever seen how a small missed step can cause big trouble? That’s why procedures are critical.

Compliance With Regulations

Safety policies must align with local and national electrical safety regulations. Ignoring legal requirements can lead to penalties and puts workers at risk. You should regularly check for updates from organizations like OSHA or the National Electrical Code.

Integrate compliance into your policies so it becomes part of daily practice, not just a checkbox. This also shows your commitment to safety beyond just internal rules. How often do you review your policies against current regulations to ensure you’re fully compliant?

Training And Education

Creating a robust electrical safety program requires more than just rules and equipment. Training and education are the backbone of any safety initiative. Without proper knowledge, employees may unknowingly expose themselves or others to serious risks. Let’s break down the core elements of training and education that can make your program effective and sustainable.

Employee Safety Training

Employee safety training is the first step to building a culture of awareness. It ensures that every team member understands the basics of electrical hazards and safe practices. From identifying risks like exposed wires to knowing the proper response to electrical shocks, training equips employees with life-saving skills.

Interactive sessions, such as hands-on workshops or real-life simulations, can make the learning process engaging. Pair this with clear visual aids and concise manuals to ensure concepts stick. Ask yourself: have you equipped your team to recognize danger before it strikes?

Specialized Electrical Training

Not all employees need the same level of expertise. Specialized electrical training is essential for those working directly with electrical systems or high-voltage equipment. This type of training dives deeper into technical skills, such as lockout/tagout procedures and circuit analysis.

Consider tailoring these sessions to match your industry’s unique challenges. For example, a manufacturing plant may focus on machinery-related electrical risks, while a construction site prioritizes safe handling of temporary power sources. Are your specialized workers prepared for the complexities they face daily?

Ongoing Skill Development

Training isn’t a one-time event. Electrical safety standards evolve, and so should your team’s skills. Ongoing skill development keeps employees sharp and aware of new technologies and methods. Regular refreshers prevent complacency, which can be as dangerous as ignorance.

Schedule periodic training updates and certifications to maintain compliance and build confidence. Encourage open discussions where employees can share experiences and lessons learned. When was the last time you checked if your team’s knowledge matched current safety protocols?

Implementing Safety Controls

Implementing safety controls is essential in developing an effective electrical safety program. These controls help minimize risks and ensure a safe working environment. By focusing on proper equipment, procedures, and practices, you can prevent electrical hazards and protect workers from harm.

Use Of Personal Protective Equipment

Personal protective equipment (PPE) is vital for worker safety during electrical tasks. Items like insulated gloves, face shields, and arc-rated clothing reduce exposure to electrical hazards. Ensure all PPE meets industry standards and is regularly inspected. Train employees on proper usage to maximize effectiveness and prevent accidents.

Lockout/tagout Procedures

Lockout/Tagout (LOTO) procedures are critical for controlling energy sources. These procedures prevent accidental activation of electrical systems during maintenance. Use clear, durable tags and locks to identify de-energized equipment. Train workers on LOTO steps and enforce compliance to ensure safety.

Safe Work Practices

Safe work practices minimize risks during electrical work. Always de-energize circuits before starting any task. Maintain a safe distance from live parts and use insulated tools. Establish guidelines for working in confined spaces or near wet environments. Regular training helps workers stay informed and follow these practices.

Monitoring And Inspections

Monitoring and inspections form the backbone of any effective electrical safety program. They ensure hazards are identified early and risks are minimized. Regular checks help maintain a safe work environment and protect both workers and equipment from harm.

These activities provide ongoing assurance that safety standards are met. They also highlight areas needing improvement before accidents occur. A well-structured monitoring plan makes safety a continuous priority.

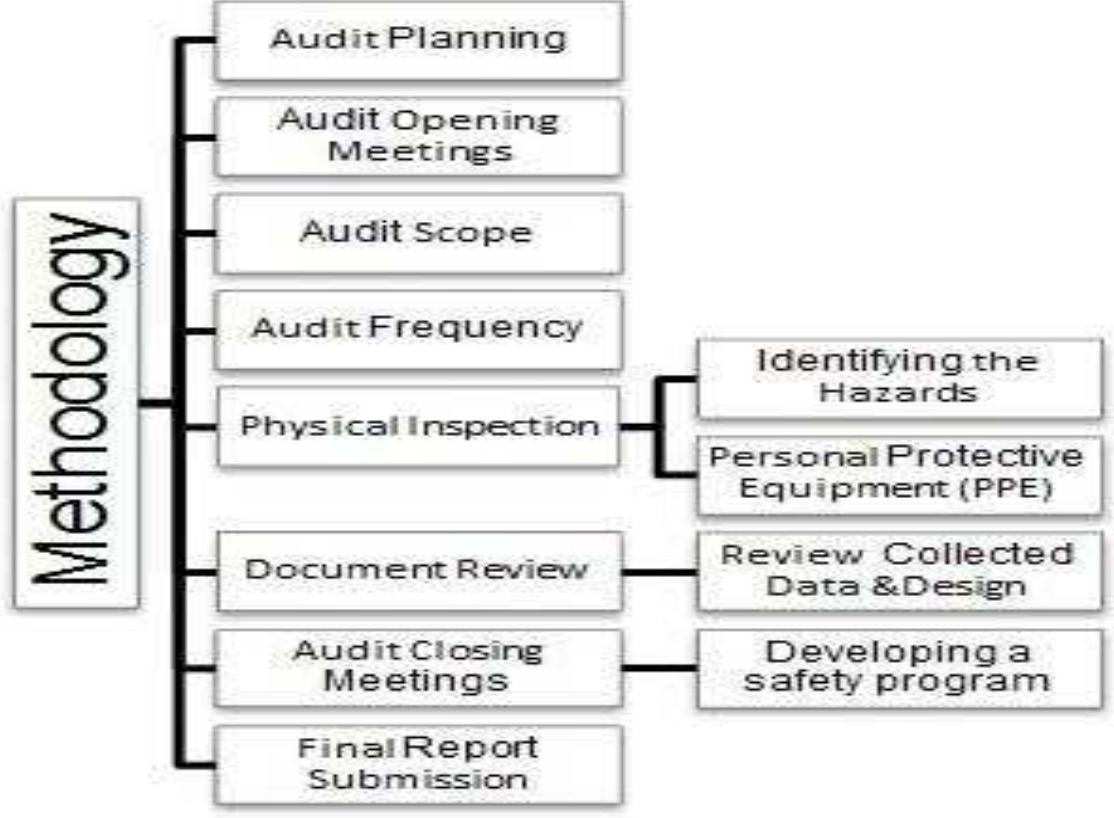

Regular Safety Audits

Conduct safety audits frequently to review all electrical systems and procedures. Audits assess compliance with safety rules and regulations. They spot unsafe conditions or behaviors that could cause accidents.

Use checklists to cover every aspect of electrical safety. Involve trained personnel who understand electrical hazards. Document findings clearly and take prompt action on risks found.

Equipment Maintenance Checks

Inspect electrical equipment regularly to ensure it works properly. Look for signs of wear, damage, or faulty wiring. Proper maintenance prevents malfunctions that can lead to shocks or fires.

Schedule routine testing of devices like circuit breakers and grounding systems. Keep detailed records of all maintenance activities. Replace or repair faulty equipment immediately to maintain safety.

Incident Reporting Systems

Set up a clear system for reporting electrical incidents or near misses. Encourage workers to report issues without fear of blame. Early reporting helps address problems quickly and prevent repeats.

Track all reports carefully to identify patterns or recurring hazards. Use this data to improve safety measures. Train staff on how to report incidents correctly and promptly.

Credit: www.youtube.com

Emergency Preparedness

Emergency preparedness is a key part of any electrical safety program. It helps protect workers and reduce risks during electrical accidents. Planning ahead ensures quick and effective action when emergencies happen. This section covers essential steps to prepare for electrical emergencies.

Response Planning

Response planning involves creating clear steps for handling electrical accidents. Plans should include:

- Identifying potential electrical hazards

- Assigning roles and responsibilities

- Establishing procedures to shut off power safely

- Providing training on emergency actions

Effective response plans help reduce injury and damage. Regular drills keep the team ready and confident.

First Aid And Rescue

First aid and rescue training is crucial for electrical safety. Workers must know how to:

- Recognize electrical shock symptoms

- Perform CPR and basic first aid

- Use rescue equipment safely

- Avoid further harm during rescue

Quick first aid can save lives. Rescue skills should be updated regularly to stay effective.

Communication Protocols

Clear communication is vital during electrical emergencies. Protocols should cover:

- How to report incidents immediately

- Who to contact for help

- Using alarms and signals effectively

- Sharing updates with all team members

Good communication prevents confusion and speeds up emergency response.

Continuous Improvement

Electrical safety is not a one-and-done process. It requires ongoing effort to adapt, learn, and improve. A strong safety program thrives on continuous improvement, ensuring risks are minimized and employees are protected.

Feedback Mechanisms

Feedback is the backbone of any improvement process. Encourage employees to share their experiences and insights about safety practices. Anonymous surveys, suggestion boxes, or regular team meetings can make this process easier and more effective.

Pay close attention to near-miss incidents. These are golden opportunities to identify gaps in your program before they escalate into accidents. Ask yourself, “What could we have done differently to prevent this?”

Once you gather feedback, act on it promptly. Employees are more likely to contribute if they see their input leading to tangible changes.

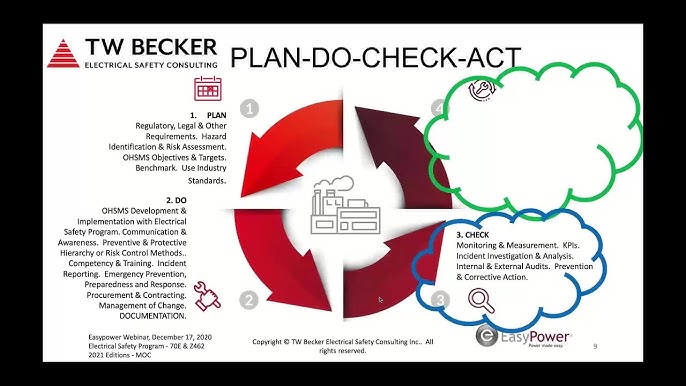

Updating Safety Programs

Safety standards evolve, and so should your program. Review your electrical safety procedures at least once a year to ensure they align with current industry regulations. Neglecting updates can leave your workforce exposed to avoidable risks.

Think about your workplace dynamics. Have you added new equipment or changed workflows? If yes, your safety program needs a refresh to address these changes effectively.

Keep your team in the loop when updates are made. Training sessions or quick refresher courses can help everyone stay on the same page.

Incorporating New Technologies

Technology is your ally in enhancing safety. Tools like infrared thermography can help identify electrical issues before they become dangerous. Have you considered using wearable safety devices? They can monitor real-time conditions and alert employees to potential hazards.

Automation is another game-changer. Smart systems can shut off power when anomalies are detected, reducing the need for human intervention in high-risk situations.

Don’t let the fear of complexity hold you back. Start small by adopting one tool and expanding as you see results. The goal is to make safety smarter, not harder.

Credit: www.scribd.com

Frequently Asked Questions

What Is An Electrical Safety Program?

An electrical safety program is a structured plan to identify, manage, and mitigate electrical hazards. It ensures workplace safety and compliance.

Why Is Developing An Electrical Safety Program Important?

Developing an electrical safety program prevents accidents, ensures compliance, and promotes awareness. It protects workers and improves workplace efficiency.

What Are The Key Elements Of An Electrical Safety Program?

Key elements include hazard identification, risk assessment, training, procedures, personal protective equipment, and regular safety audits.

How Do You Start Creating An Electrical Safety Program?

Start by assessing risks, identifying hazards, and establishing safety protocols. Provide training and ensure proper documentation for compliance.

Conclusion

Creating a strong electrical safety program protects workers and equipment. Clear rules help prevent accidents and injuries. Regular training keeps safety knowledge fresh and useful. Always check and update your safety plan. Safety is a team effort that needs everyone’s attention.

Small steps lead to big improvements in safety. Stay alert, follow guidelines, and encourage others to do the same. Safety saves lives and keeps work going smoothly. Never take risks with electricity—it is powerful and dangerous. A good program means safer work for all.